Key highlights:

1. Improved labor productivity: Only two workers are needed to operate four edge banding machines, saving 75% of labor.

2. Reduced landing times: The four edges are sealed only once, and the plate passing efficiency is high.

3. The integrated frame is equipped with high-strength aluminum materials, and the entire line runs smoothly, ensuring the quality of edge banding.

4. Suitable for conveying plates of different sizes: the minimum plate size is 200*200mm, and the maximum length-to-width ratio of the plate is 7:1 (depending on the customer's plate situation).

5. The roller drive adopts variable frequency control, which can flexibly match the speed of the roller conveyor platform with the operating speed of the edge banding machine, and the plate conveying is stable.

6. The integrated power side leaning device and the power-assisted feeding and discharging device assist in the stable conveying of the plates.

7. Independent control of the electrical box and operation panel facilitates manual operation and maintenance.

8. Independent PLC control system facilitates production line layout and modular docking between equipment.

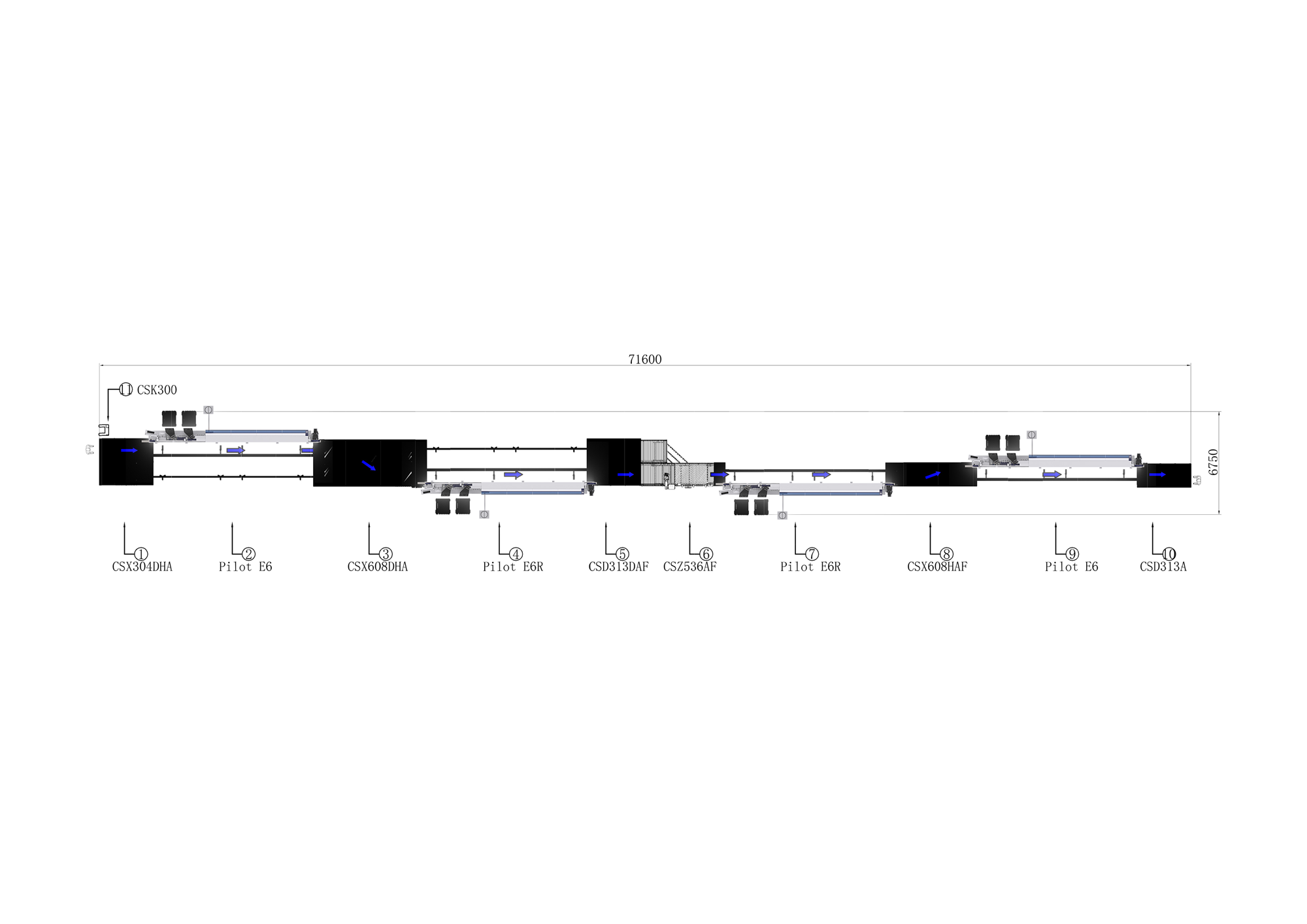

Pilot E6 Four Machines Line

Product Details

|

Technical Parameters |

Details |

|

Maximum processing size (L*W) mm |

2400*1200 |

|

Minimum processing size (L*W) mm |

200*200 |

|

Workpiece length mm |

200 - 2400 |

|

Workpiece width mm |

200 - 1200 |

|

Workpiece thickness mm |

10 - 40 |

|

Workpiece length - width ratio |

≤ 7:1 |

|

Height of worktable from ground mm |

930 - 960 (adjustable) |

|

Feed speed m/min |

26 (matches edge bander speed) |

|

Overall dimension m |

71.6 (L)*6.75 (W)*1960 (H) |

|

Working air pressure MPa |

0.6 |

|

Wired control system |

Configured as per customer needs |

|

Edging sequence |

Short edges first (long edges first optional) |