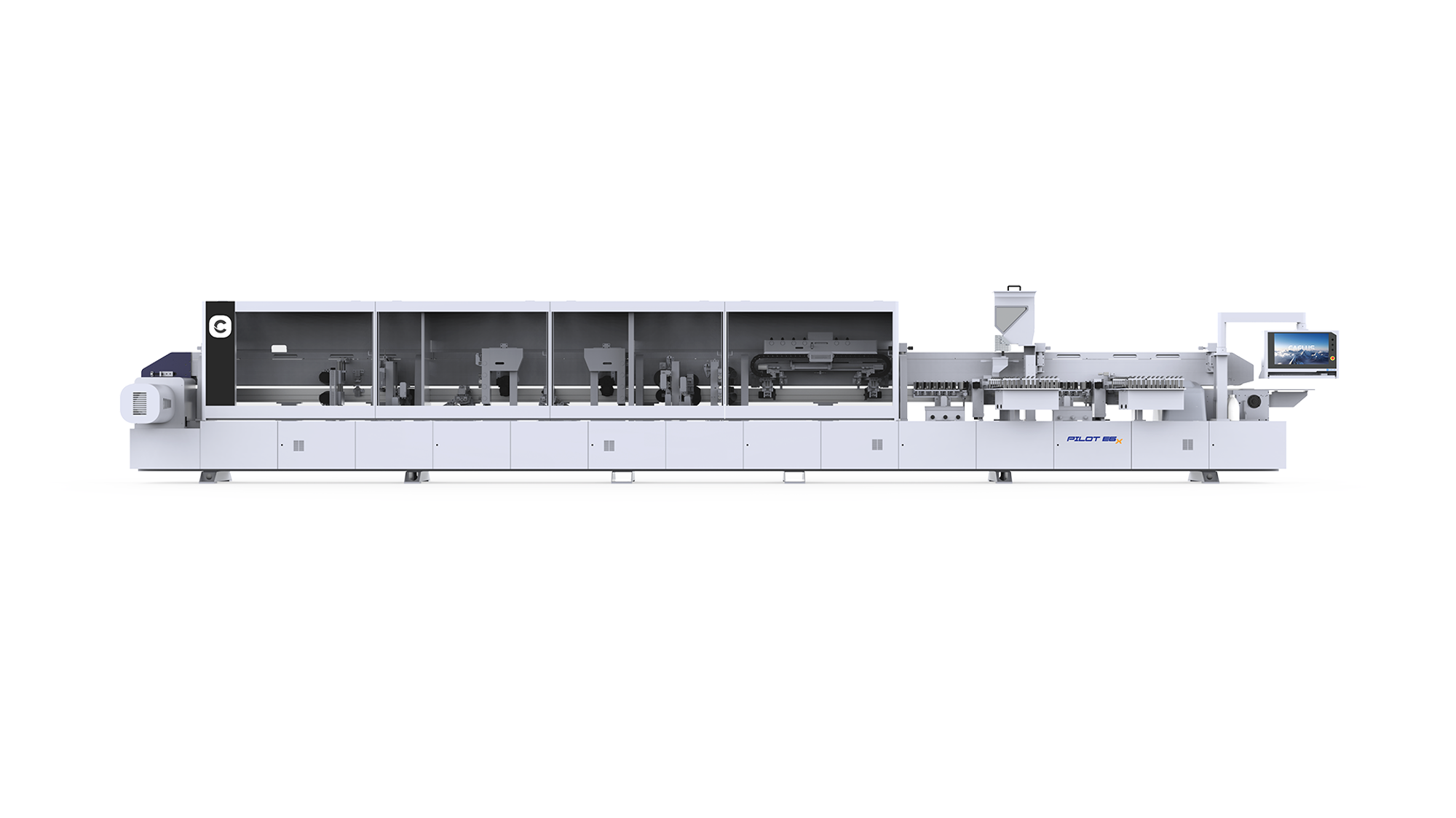

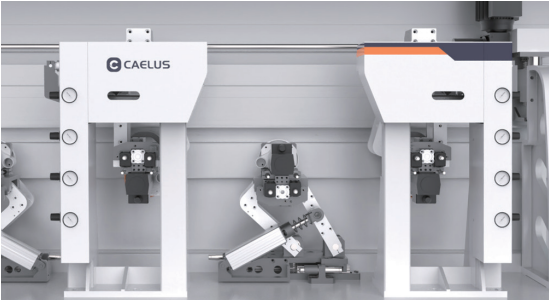

The heavy-duty steel structure frame is equipped with servo positioning system, dual coils servo controlled magazine, 32m/min horizontal snipping, heavy-duty four motor corner rounding, double buffing and waxing unit and other high-performance configurations, all to guarantee the high quality production of your furniture factory.

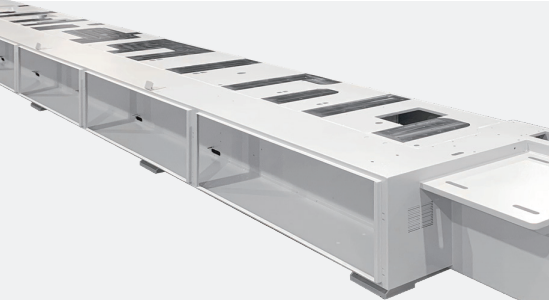

The heavy-duty steel structure frame: steel pressure beam, steel guide rails, steel frame with fine finish

processing.

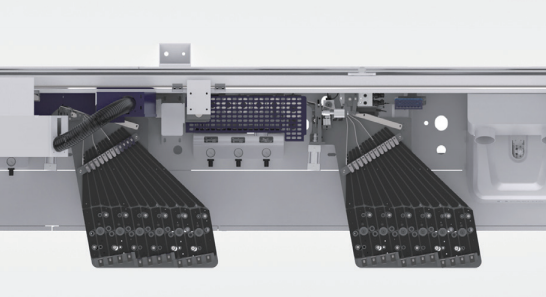

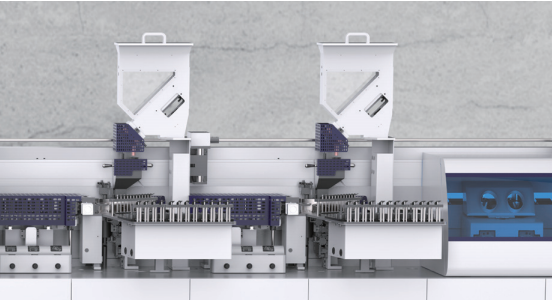

12+12 coils servo controlled magazine.

Seven pressure rollers with intelligent positioning control.

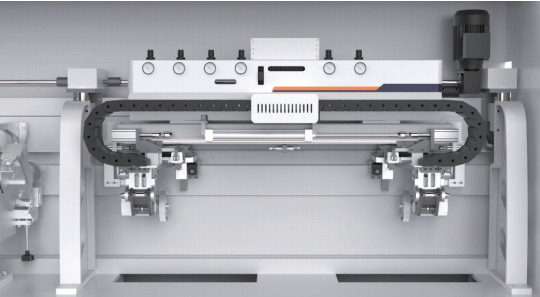

Automatic Pressure Beam Positioning

The machine is equipped with an automatic pressure beam positioning function, which automatically positions the pressure beam based on the workpiece thickness.

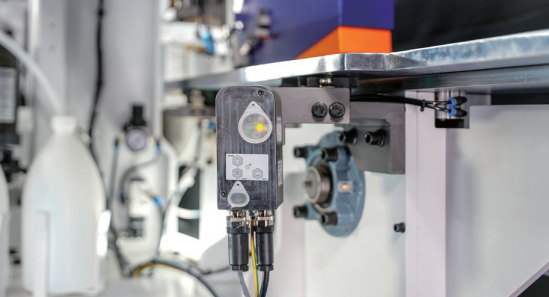

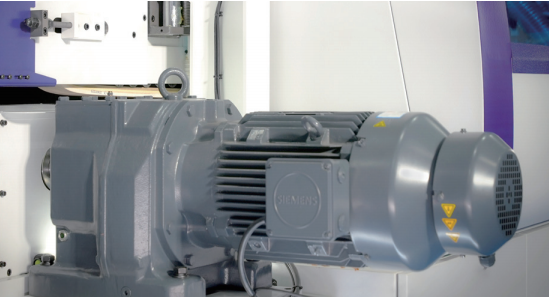

Electric Grease Pump

Automatically lubricates the guide rails with grease

according to the equipment's operating time,enhancing equipment stability.

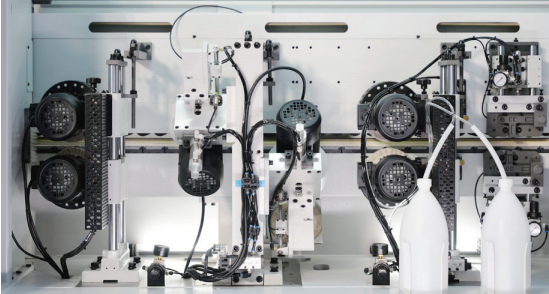

Multiple edge-banding process configurations

EVA + dual-color PUR / Laser + dual-color PUR / 2 sets of EVA / 2 sets of dual-color PUR.

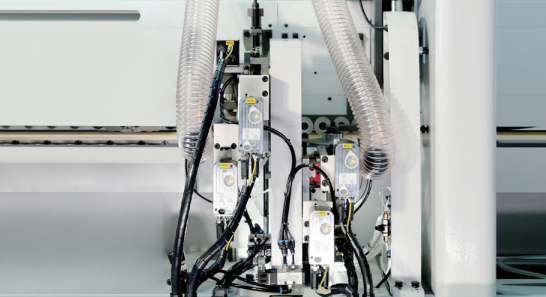

High speed horizontal snipping unit with 25 degree chamfer cutting, Maximum speed 32m/min.

Heavy-duty high speed four motor corner rounding, can switch two positions for different edge thickness.

Dual tracing wheels on fine trimming and scraping with intelligent positioning.

Double buffing and waxing unit, improve surface brightness.

World-class electronic control components and systems.