Standard Functions:

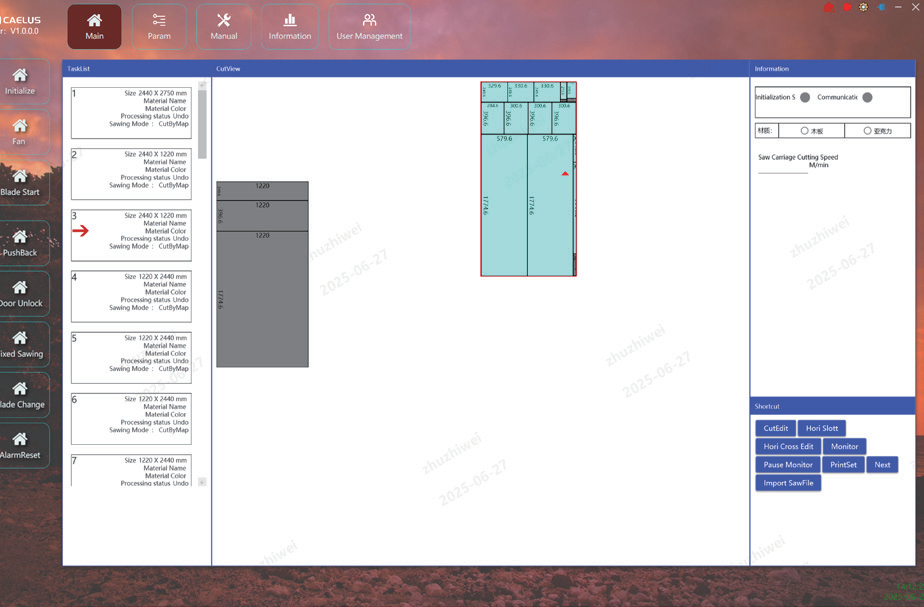

1. Intelligent Sawing Control System

- Ultra-simple Interaction: No redundant settings,straightforward operation.

- Smart Categorization: Parameters modularized byfunction for instant access.

- One-tap Selection: Dropdown. parameter presetseliminate manual input.

- Customizable Theme: Personalize operationbackground to preference.

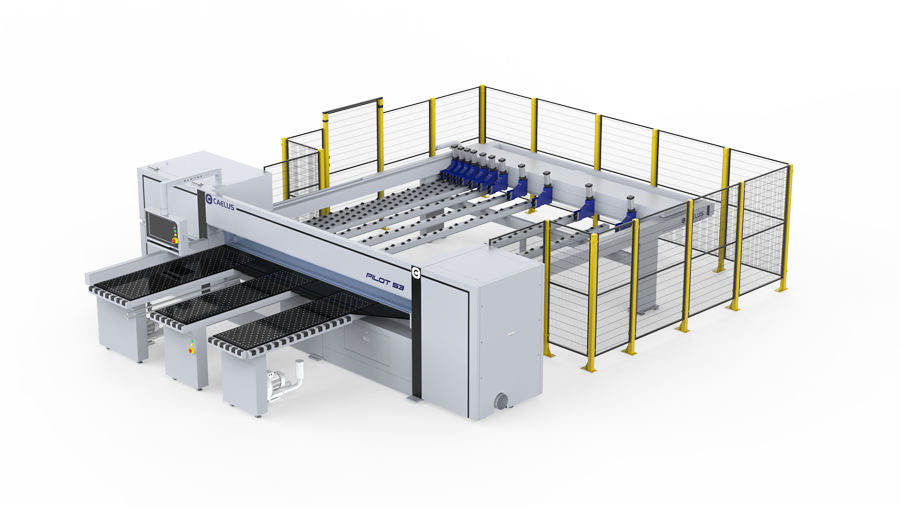

2. Heavy-Duty Machine Frame

The high-rigidity, heavy-duty frame is annealed,sandblasted, and processed to ensure long-termstable operation without defommation.

3. Quick Start Device

Equipped with a start cycle bar, ergonomically designed to make the cutting start easier and faster.

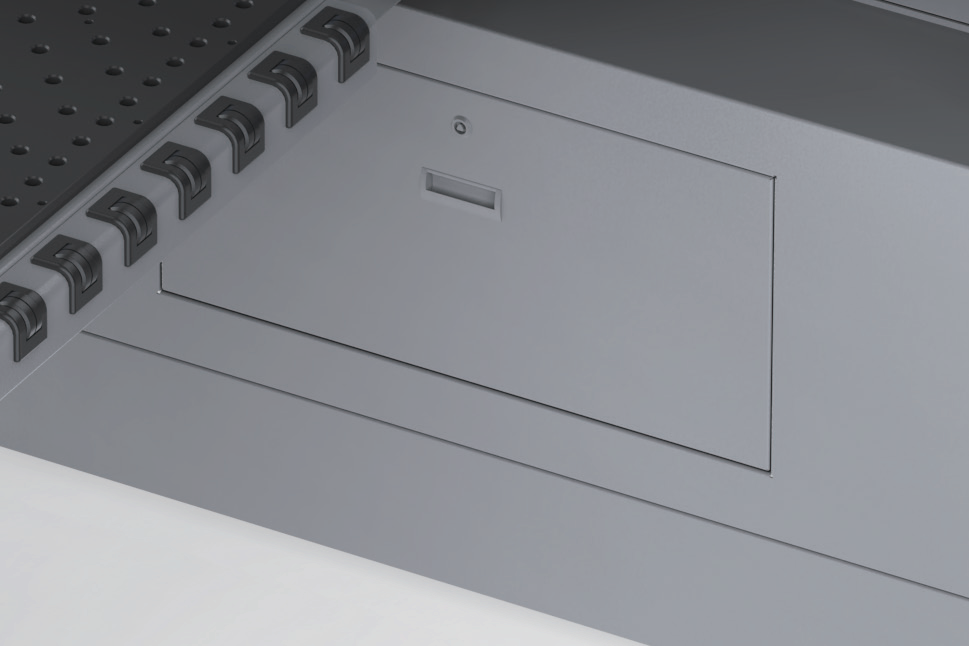

4. Quick Clean Window

Cleaning position, allowing easy removal of cutting waste.

5. Smart Saw Carriage Positioning System

The cutting can automatically adjust according topanel size to reduce idle travel and improve workefficiency.

6. Main Saw Servo Elevation

The main saw's lifting is servo-controlled. lt canautomatically adjust the rising height according tothe panel thickness and has an accurate groovingfunction.

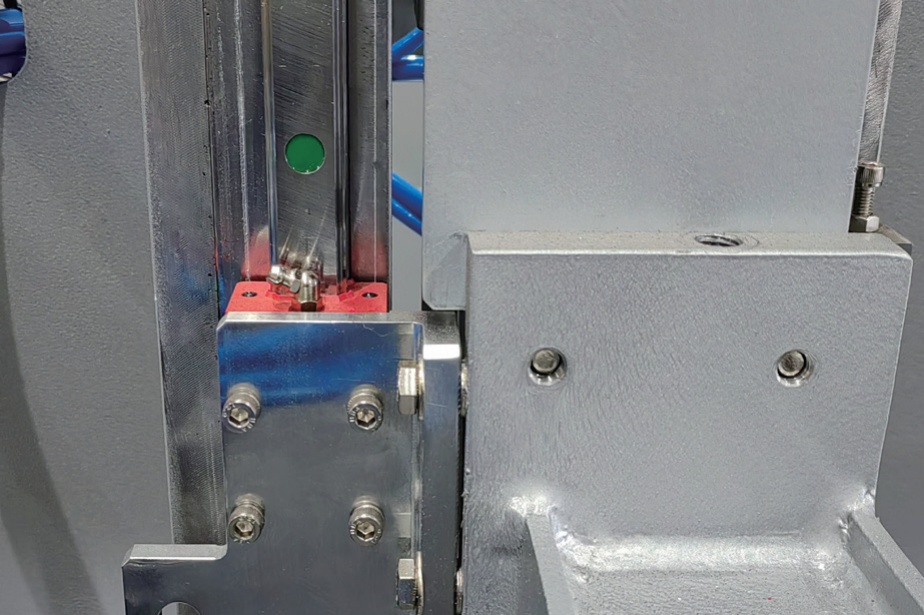

7. Festo Pneumatic Unit

The machine is equipped with Festo's Filter-Regulator-Lubricator unit, a precision pressure regulator, hydrolysis-resistant hoses, and an electronic pressure gauge. This configuration ensures clean and stable air supply, with the regulator enabling precise control of air pressure.The hoses are designed to with stand harsh operating conditions, while the gauge provides real-time monitoring of pressure.

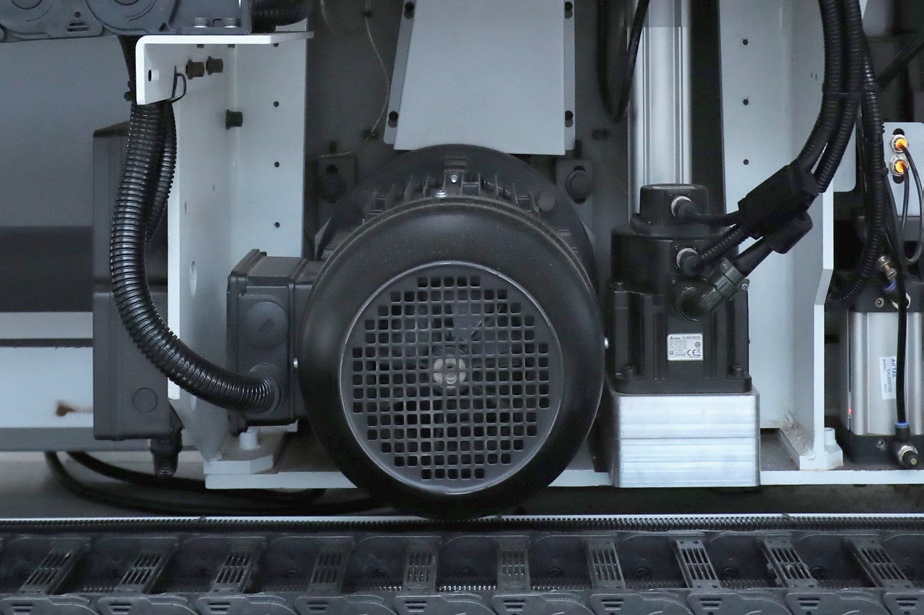

8.22kW PermanentMagnet Synchronous Drive

The 22kW permanent magnet synchronous drive system offers high torque and low noise.

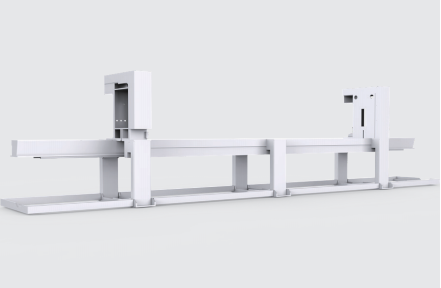

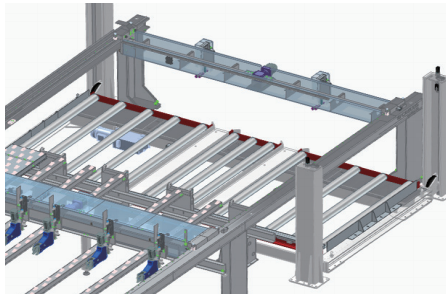

9. Saw Carriage Guiding System

The drive system of the saw carriage utilizes a linearguide rail structure characterized by exception alrigidity, high precision and superior dust-resistance.

10.Linear Guide for Pressure Beam

The pressure beam, guided by linear guide rails,moves up and down more smoothly. With the"Adaptive Pressure Control for Pressure Beam"option, it can automatically adjust the pressure.

11.Intelligent optical sawing Auxiliary System

Integrates real-time dynamic tracking of the sawcarriage, vision-assisted panel alignment guidance,and predictive machine status monitoring.

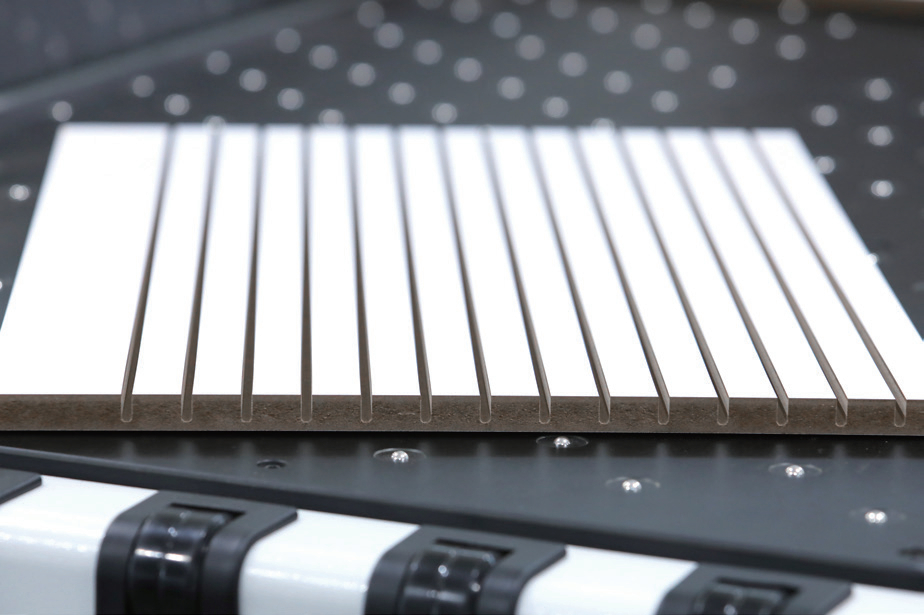

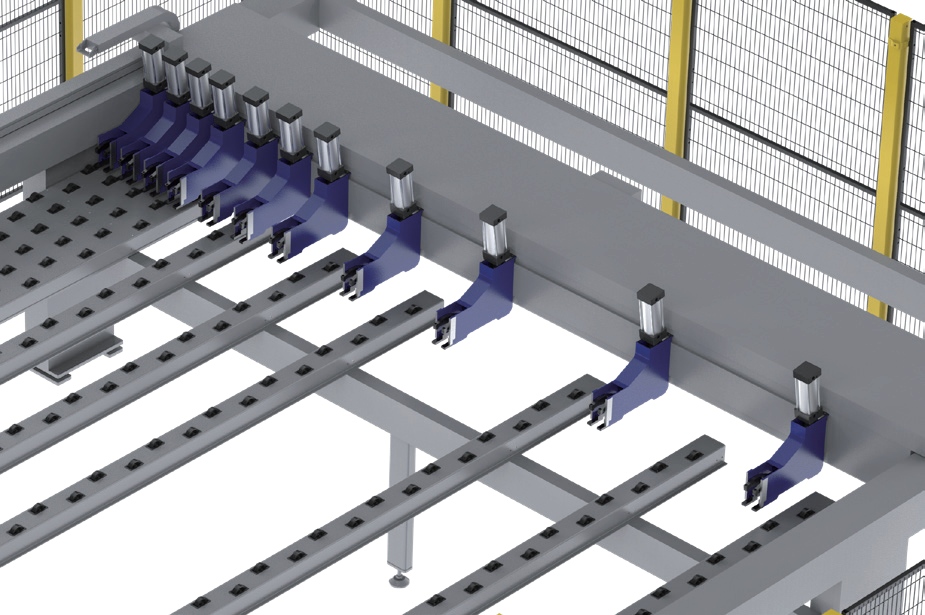

12. High Density Clamps

With higher density clamps, the system can firlygrip the boards, ensuring optimal sawing results.

Optional Features:

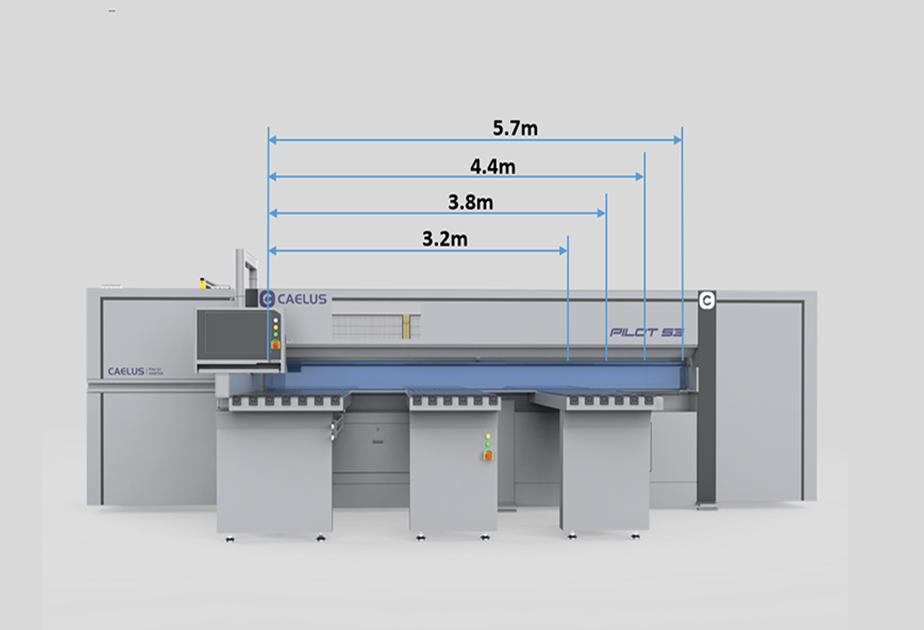

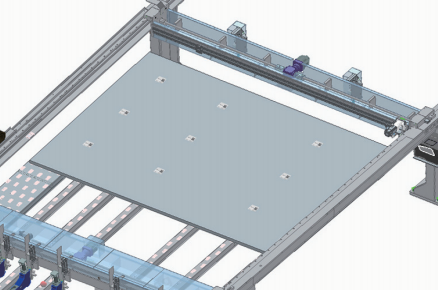

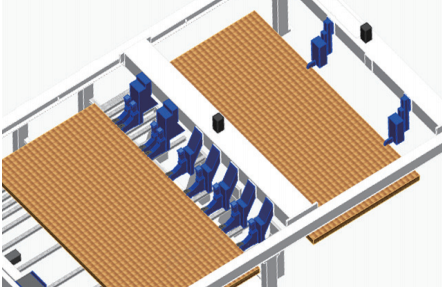

1.Customized Worktables Size

Customers can independently select equipment specifications based on their factory's panel processing requirements, with customized worktables covering the full size range of 3.2m to 5.7m. This solution precisely matches equipment needs across panel processing scenarios, ensuring compatibility with standardized production lines while supporting customized requirements for flexible manufacturing.

2. Plastic Cutting Module

It can cut a wide variety of materials, including wooden boards, acrylic, nylon and other composite materials meeting the needs of furniture manufacturing, advertising, and industrial parts production.

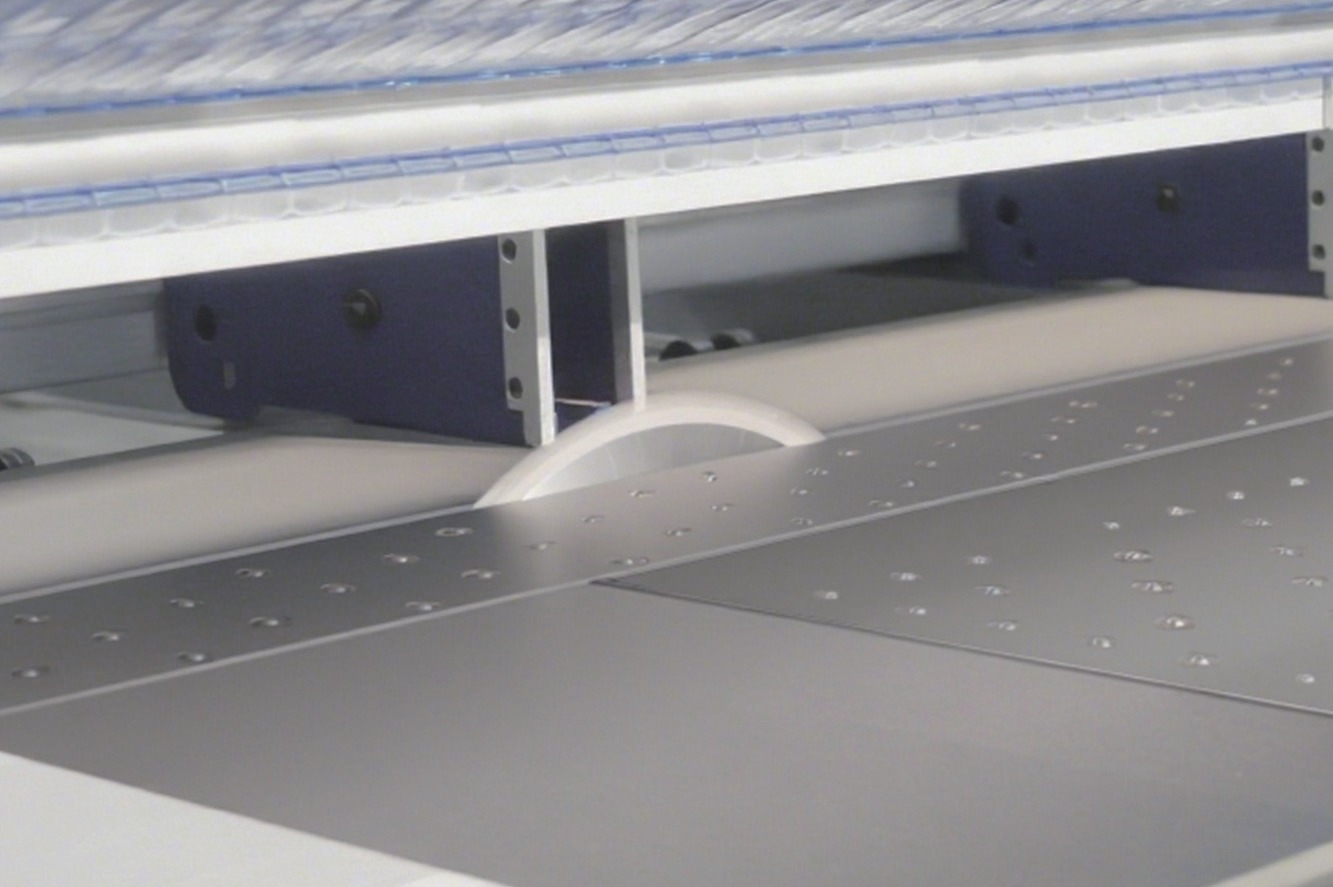

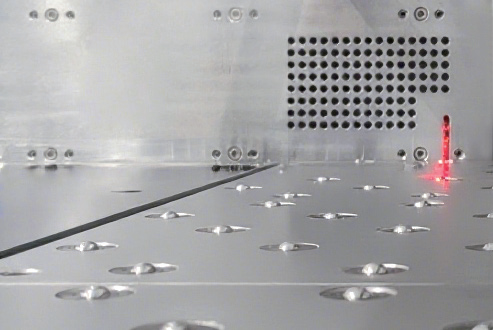

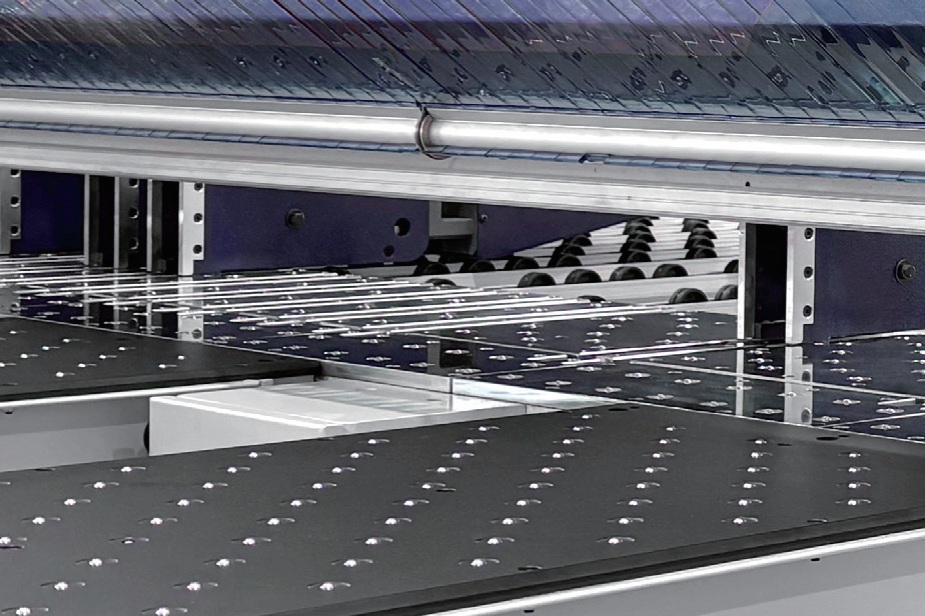

3. SteelTable

The precision-ground, hard-chrome-plated steel workbench has a high-precision surface and outstanding wear resistance. Integrated air jets facilitate the smooth movement of panels and protect materials with highly sensitive surfaces.

4.Adaptive Pneumatic Control for Pressure Beam

The pressure is automatically adjusted based on the specific type of boards, there by ensuring cutting quality while providing enhanced protection for the material.

5. Fully Automatic Labelling System

This labelling system labels the unprocessed panel before it is cut. Labelling is independent of cutting process.

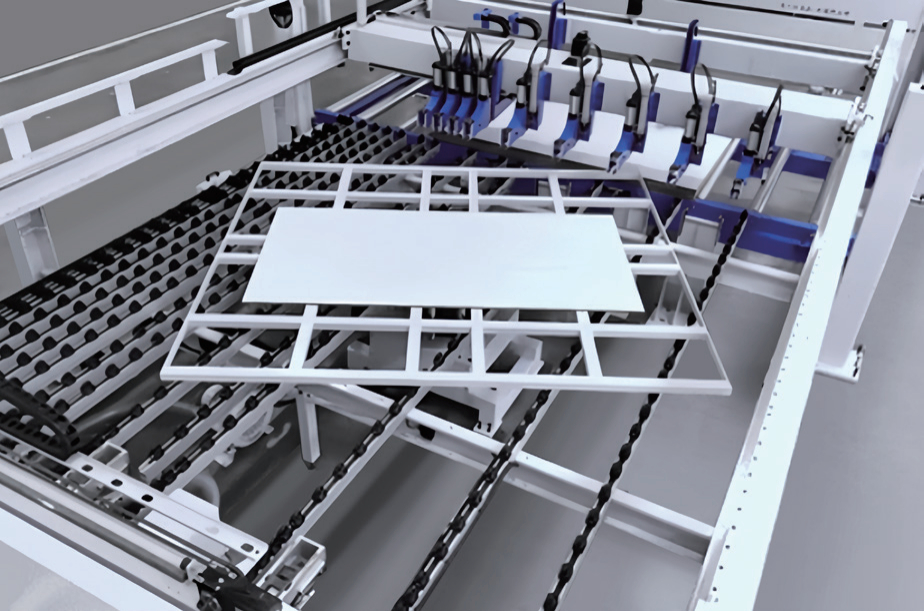

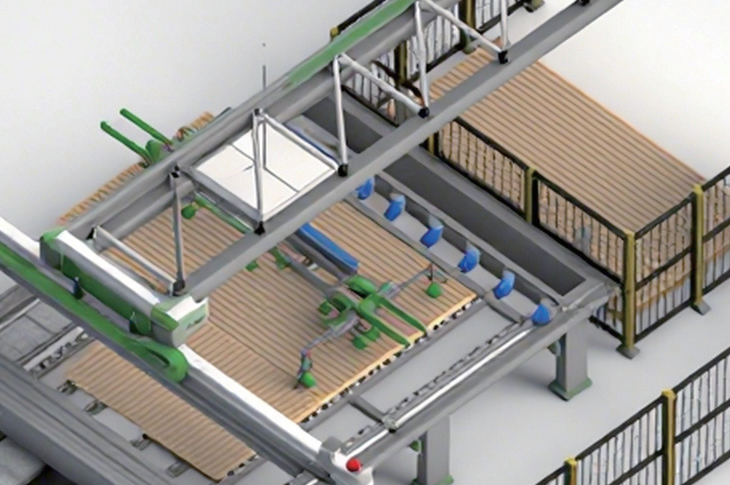

6. Turning Device

No manual operation needed.The system automatically adjusts the cutting direction to adaptto more cutting scenarios.

7. Rear Feeding Device

The heavy-duty hydraulic control system offers amaximum load capacity of up to 4T, ensuring safeand stable operation with optional roller orientation.Compared to manual loading, it achieves a 20% efficiency improvement while reducing operational costs.

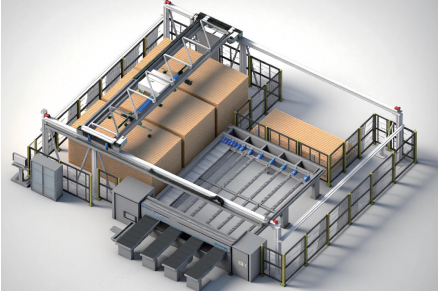

8. Panel Buffer Module

With the connection to StoreTek, this buffer system can prepare panel during previous panel'scutting process. This process saves time efficiently.Further more,this module is suitable to add automatic labelling system.

9. Connection with The Storage System

Software in connection with storage system with seamless connection, easy operating from saw to control the storage.

10.Side alignment from top

Independent dual side pressure device: During cutting, the side pressure device remains in the workposition, ensuring greater stability and reliability.

11. Twin Direction Storage Feeding

With the rotating function of the storage suctionsystem, there is no need to purchase a Turning Device for the panel saw separately-it inherently delivers the board-turning capability.