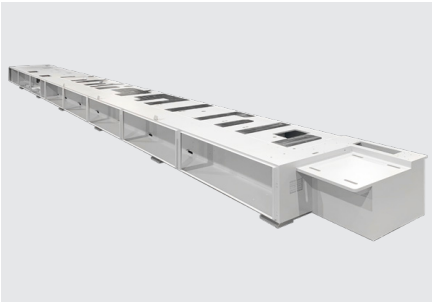

The heavy-duty steel structureframe: steel pressure beam, steelguide rails, steel frame with fine finish processing.

12+12 slots servo edge feeder /EVA (laser as option)+ Dual-color PUR.

High speed horizontal end-cutting with degree tilting, Max speed 32m/min.

Servo positioning system applied on finishing trimming and profile scraping.

Heavy-duty high speed four motor corner rounding, can switch two positions for different edge thickness.

Double buffing and waxing unit,improve surface brightness.

Core Highlights:

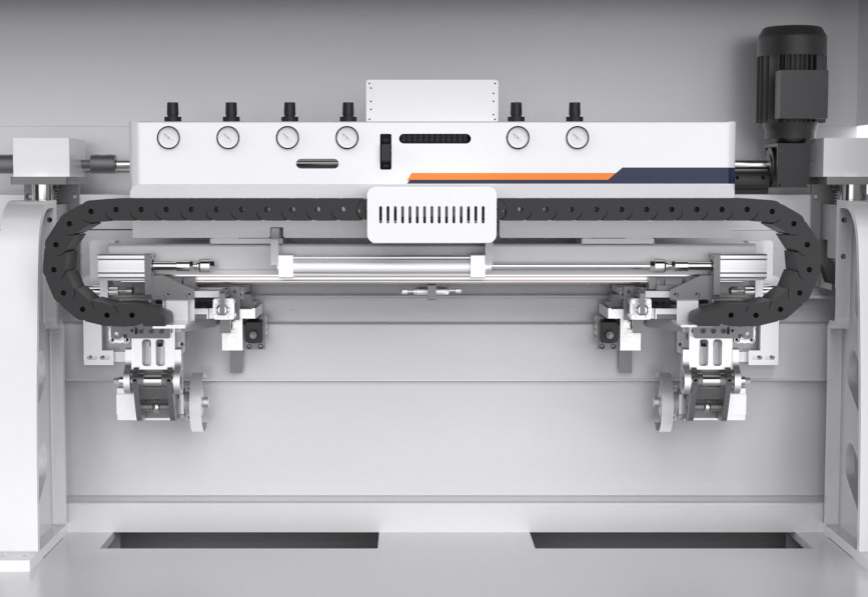

【1】【High-precision heavy-duty frame】 Steel pressure beam, steel guide rail, crawler-type pressing material, escorting 32m/min efficient and stable edge banding;

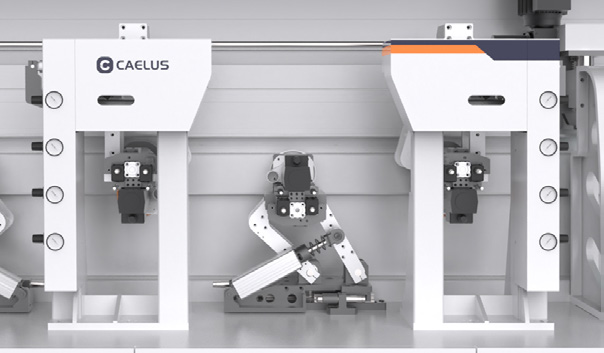

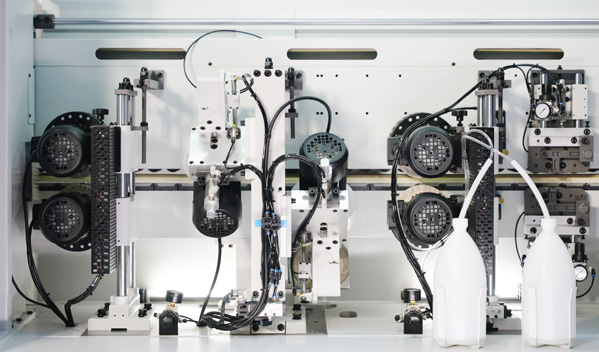

【2】【Double glue pot + double pressing mechanism】 Double glue pot can freely switch EVA (optional laser) and PUR to meet different edge banding process requirements;

【3】【Standard 12+12 channel servo feeding】 Automatic switching of multiple specifications of edge bands, easy operation, time-saving and trouble-free;

【4】【Intelligent positioning seven-wheel pressing】 Independent drive motor, intelligent switching of the pressure wheel position according to the thickness of the edge band, more reliable edge banding, improving edge banding quality;

【5】【High-speed horizontal alignment with deflection angle】 Efficient processing, perfect solution to the problem of board knocking;

【6】【Visual high-speed tracking】 Double-station tool switching function, free switching between two different thickness edge bands;

【7】【Intelligent positioning double buffer wheel trimming and scraping】 Equipped with double buffer wheels to mitigate impact, Improve edge banding quality; the intelligent positioning motor automatically adjusts the tool position according to the thickness of the edge banding, and switching edge bands does not require debugging;

【8】【Standard polishing and waxing】can automatically supply wax strips to eliminate the whitening phenomenon of the edge banding after scraping, improve the brightness of the arc corners, and make the edge banding more beautiful;

【9】【Well-known brand electronic control components】have the advantages of high reliability, strong anti-interference ability, and reduced failure rate.