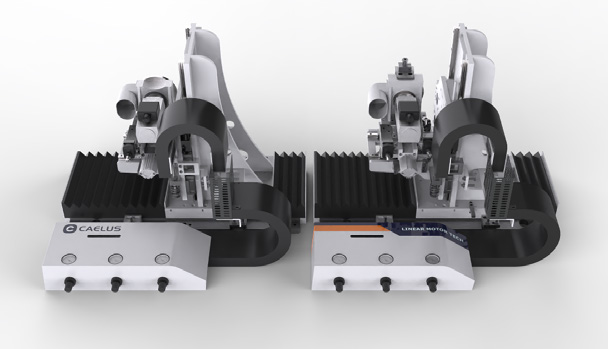

The E8 high speed intelligent edge banding machine not only meets your needs for high-qualityedge banding processes such as EVA, PUR, or laser, but also makes your production more flexible.efficient and intelligent.

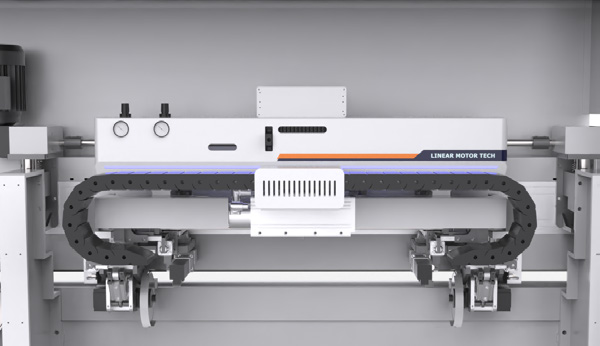

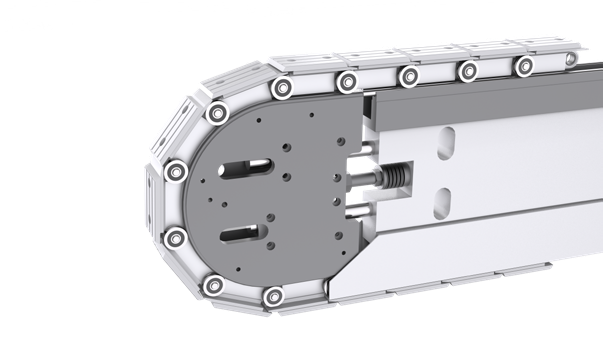

Rolling chain driven (main drive), high speed and stable.

Highlights:

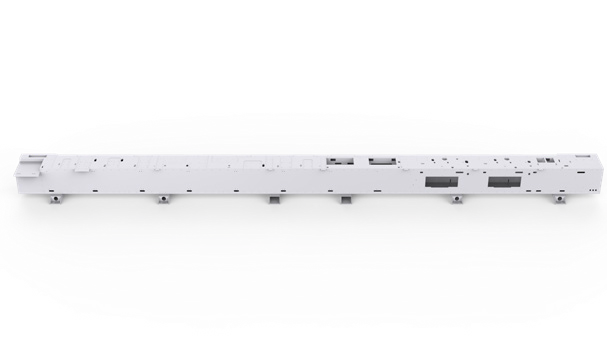

【1】【High-precision heavy-duty frame】 Steel pressure beam, steel guide rail, crawler-type pressing material, escort for 42m/min efficient and stable edge banding;

【2】【Precision chain drive】 Precision chain, made of special alloy steel precision machining, high dimensional accuracy, strong anti-deformation ability, ensure high-speed operation stability and high dimensional accuracy, ensure ultra-high-speed stability;

【3】【Double glue pot + double pressing mechanism】 Double glue pot can freely switch EVA (optional laser) and PUR to meet different edge banding process requirements;

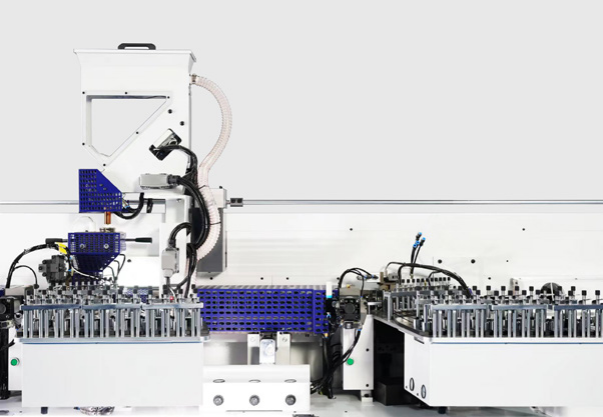

【4】【Standard 12+12 channel servo feeding】 Automatic switching of multiple specifications of edge bands, easy operation, time-saving and trouble-free;

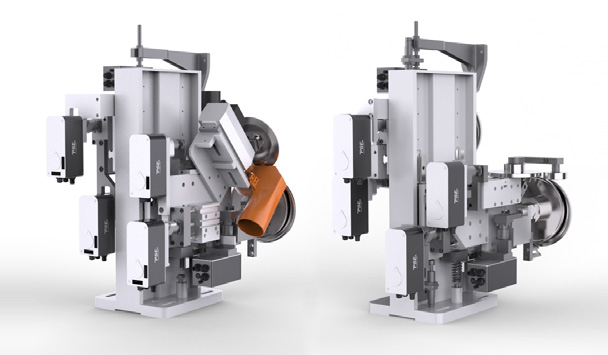

【5】【Intelligent positioning seven-wheel pressing】 Independent drive motor, intelligent switching of the pressure wheel position according to the thickness of the edge banding, more reliable edge banding, and improved edge banding quality;

【6】【Magnetic levitation horizontal end processing】 42m/min ultra-high-speed and stable end processing, perfectly solving the problem of board knocking;

【7】【Magnetic levitation tracking】 36m/min Ultra-high-speed and stable arc processing, capable of switching between two edge banding thicknesses;

【8】【Intelligent Positioning Dual Buffer Wheel Trimming and Scraping】 Dual buffer wheels mitigate impact and improve edge banding quality; the intelligent positioning motor automatically adjusts the tool position according to the edge banding thickness, eliminating the need for debugging when switching edge banding;

【9】【Well-known brand electronic control components】 High reliability, strong anti-interference ability, and reduced failure rate.