The bevel snipping unit is equipped with a saw blade with avoidance retraction function, enabling high-speed processing at 25m/min while effectively reducing the risk of workpiece collision. Tools and motors are connected via HSK interfaces, ensuring a high-gloss edge finish. A modular frequency control system enhances operational reliability, and internationally renowned pneumatic components deliver fast response and high stability. The high-strength polycarbonate viewing window ensures safety.

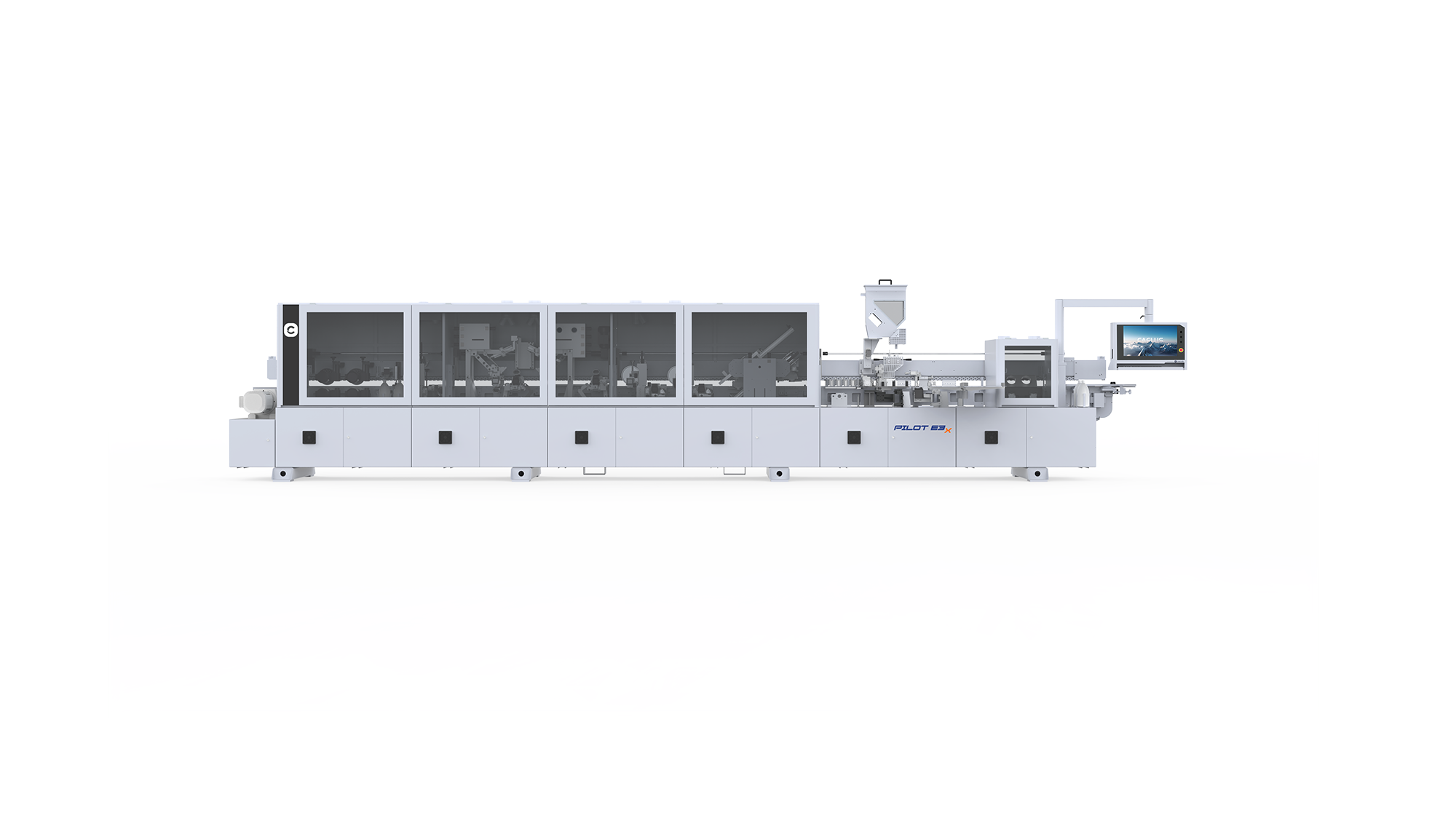

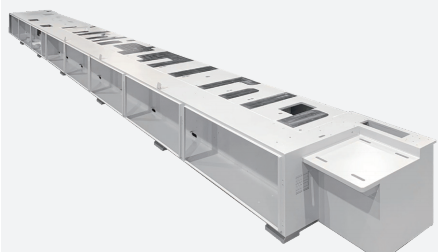

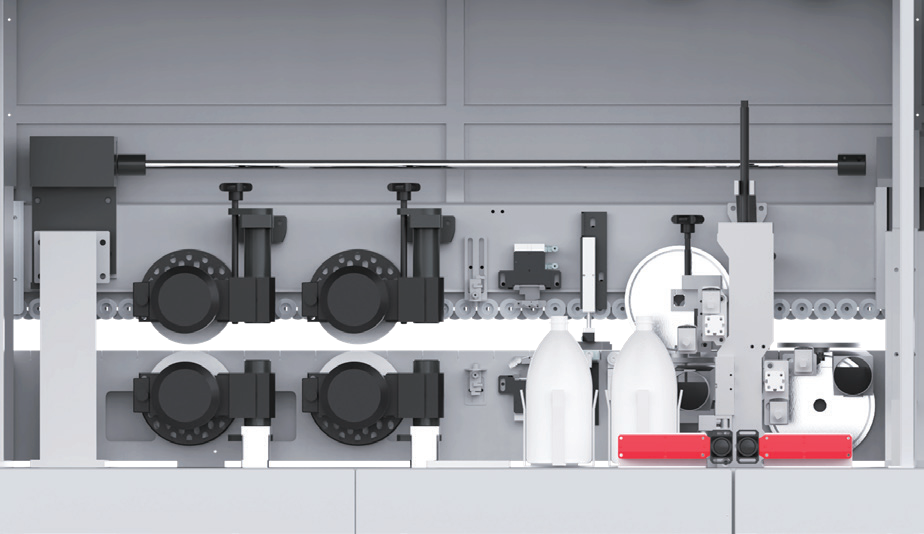

Integrated High-Precision Heavy-Duty Frame

A stress-relieved welded structure with longitudinal and transverse supports, machined with high-precision gantry processing to provide reliable support for panel transportation and processing.

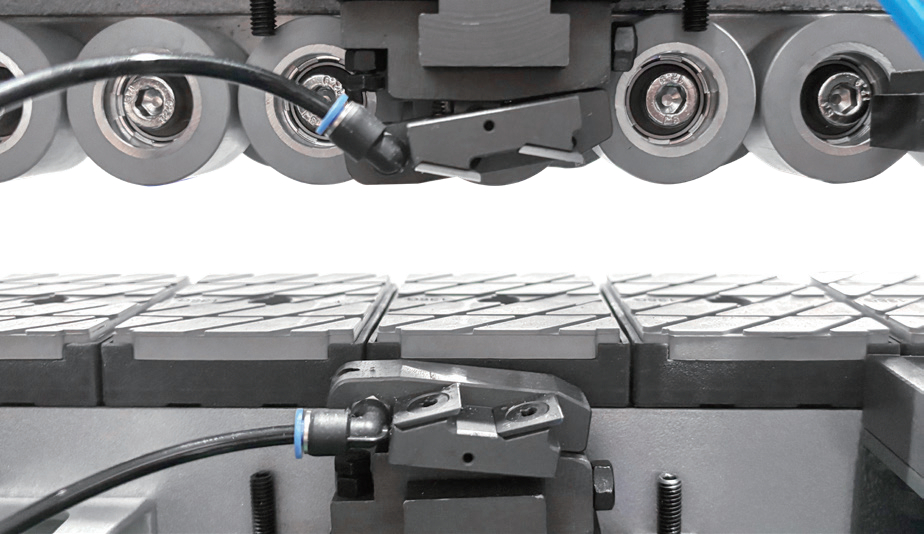

Dual Pressure Wheels + Steel Pressure Beam + Steel Guide Rail Structure

Combined with laser alignment calibration process, it delivers stable and uniform pressure force during panel processing.

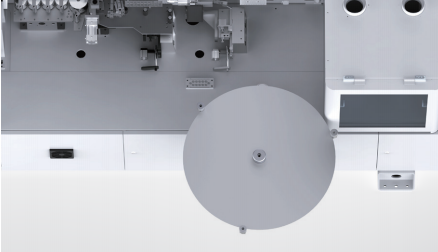

One Coil Magazine

Equipped with servo-driven edge feeding, it supports high-volume production with user-friendly and efficient operation.

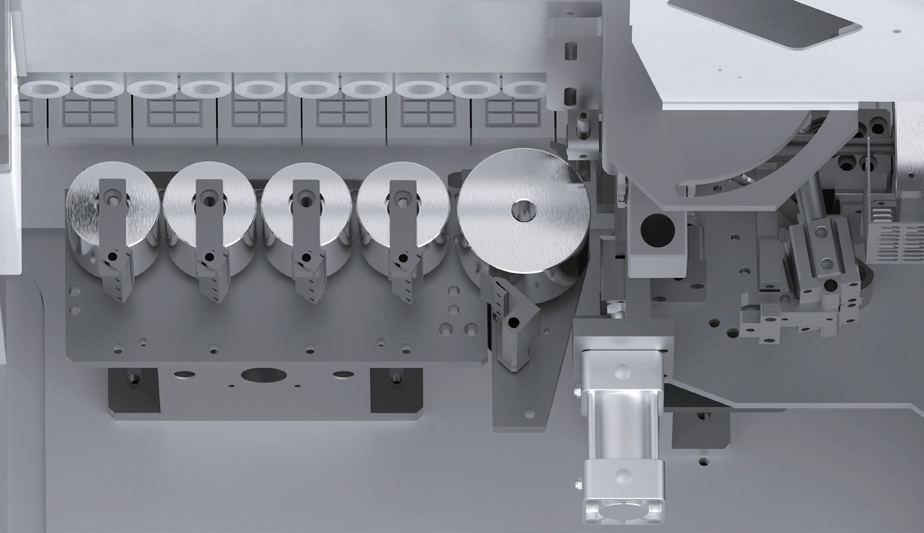

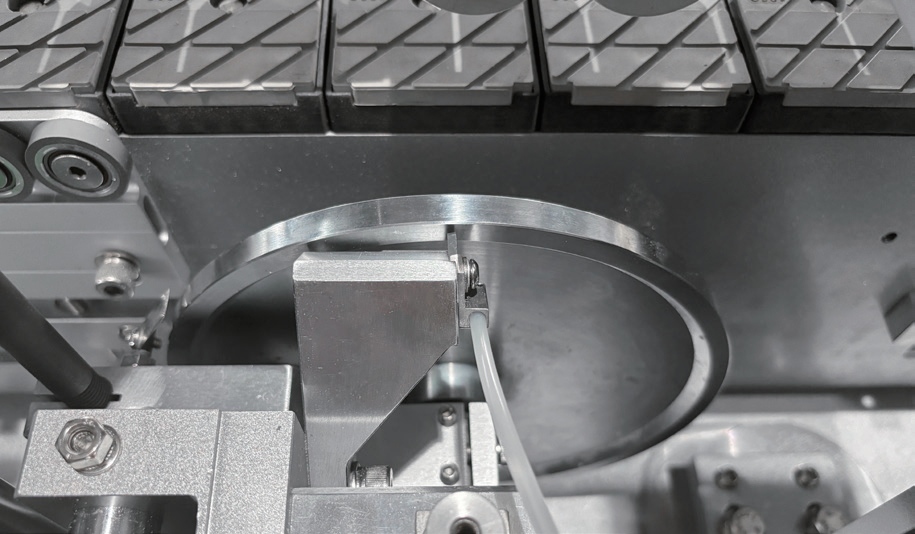

Pneumatic Five Pressure Rollers Device

Equipped with one large and four small pressure rollers, including independent drive motors, a pressure roller swing structure, glue scrapers, and cleaning fluid nozzles, with low impact on edges and boards.

Dual-color PUR Gluing Unit

Dual channels ensure even glue distribution, with monitoring, trailing edge anti-webbing, and quick adhesive switching.

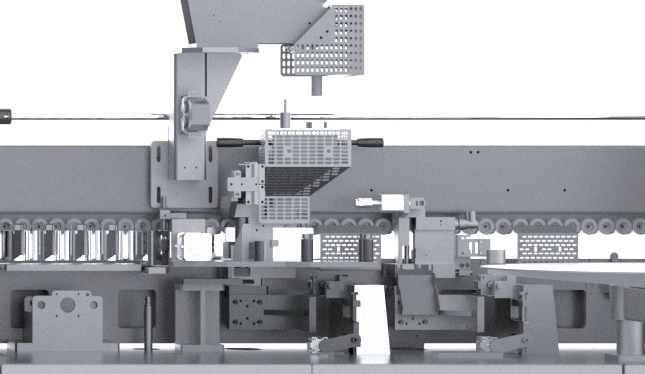

SBP25 High-Speed Snipping Unit

Stable 25m/min high-speed bevel snipping removes excess front/rear edge banding. Features rigid bracket, dust-resistant rails, saw blade avoidance

retraction function.

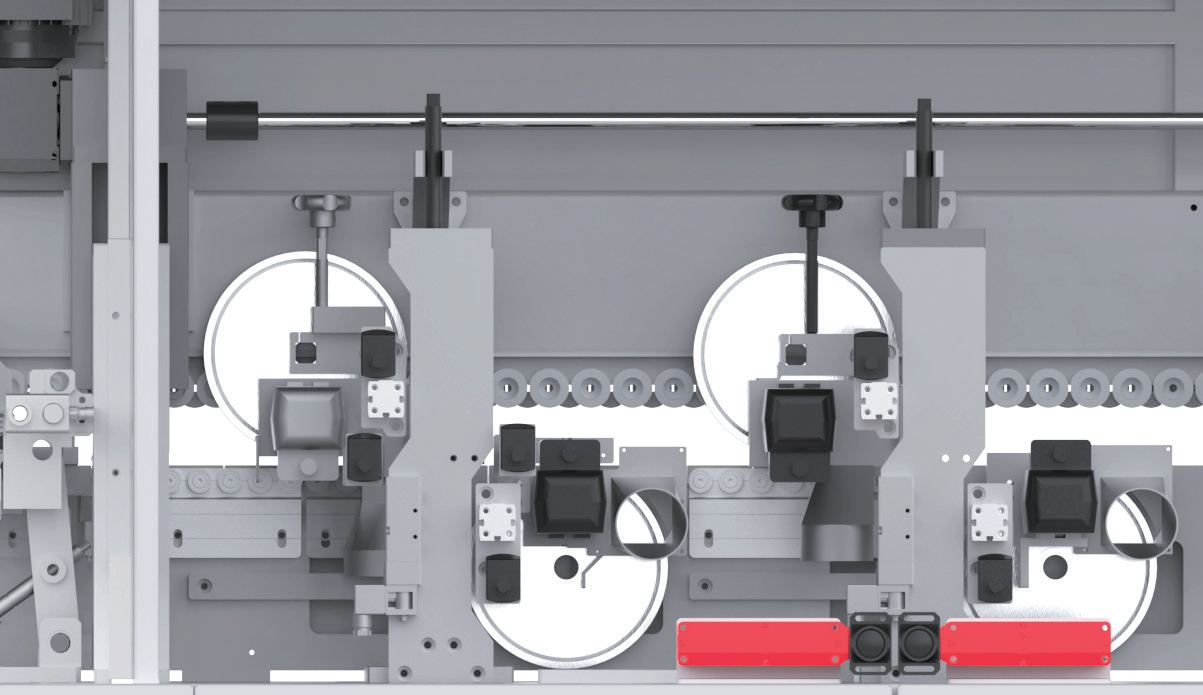

RTP20 Rough trimming / FTP20 Fine trimming Unit

Rough trimming removes excess edge banding and trims panels; fine trimming shapes edges. Steel supports and linear bearings ensure stability all with HSK inferface.

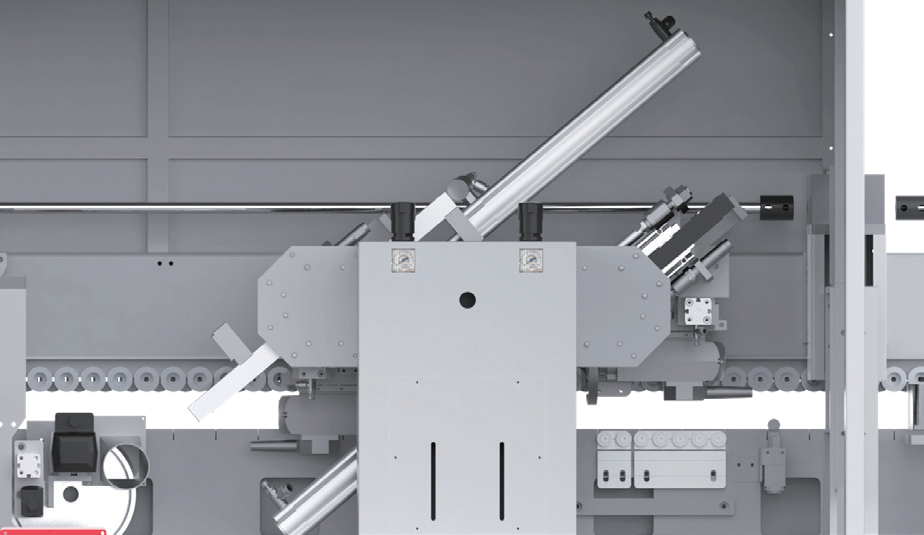

CFP25 Four Motors Corner Rounding Unit

Processes vertical edges via rigid lightweight linkages. HSK interface connections minimize runout for high finish. Precision bearings enable stable 25m/ min high-speed arc processing.

PSP20 Profile Scraping Unit

Eliminates trimming marks for a smoother panel surface. Equipped with a steel support, linear guides, and clamp-style blades to enhance both the edge finish and overall appearance.

Flexible Scraper Unit

Removes upper/lower panel residues. Integrated support shoe and cutter head for non-marking scraping, adjustable shoe accommodates deformation.

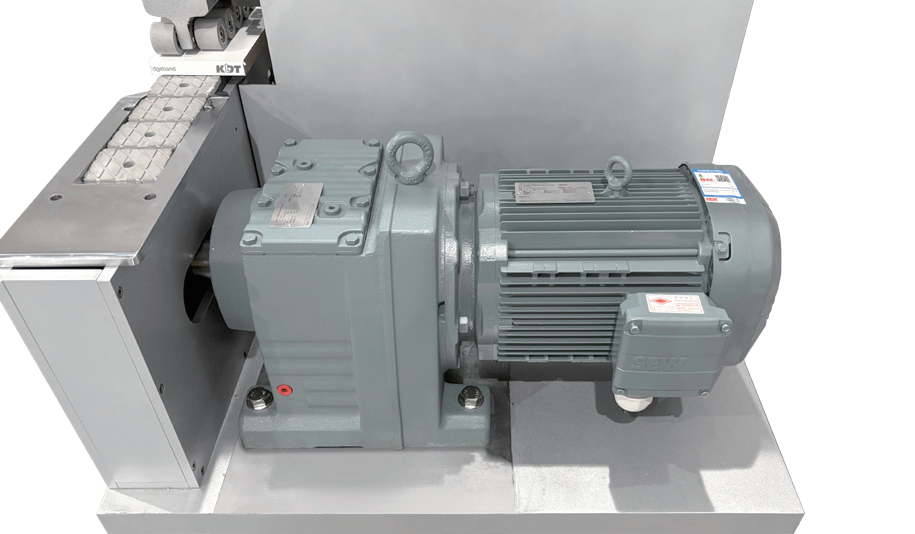

Main Driving Motor

Chain drive powers panel transport. Premium motors with low backlash, minimal speed fluctuation, ensure high-speed running with stability.

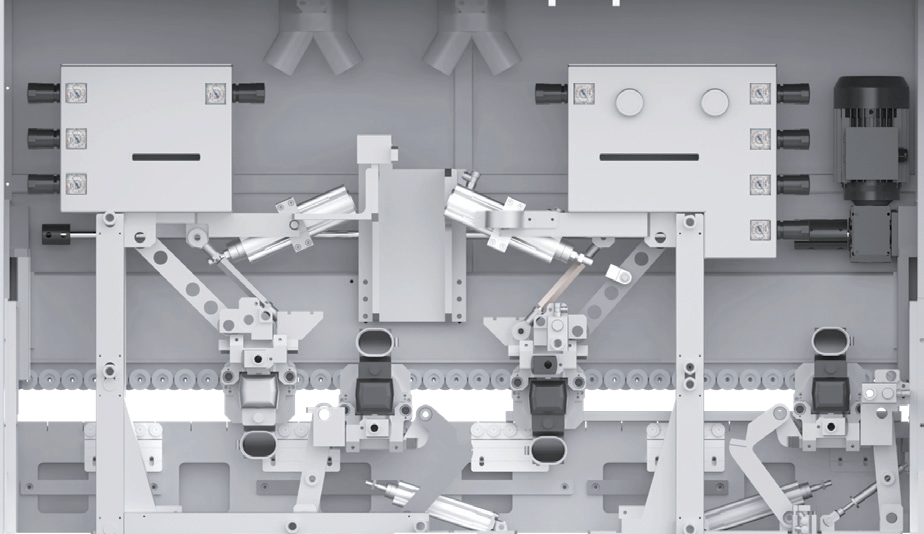

Dual Reciprocating Buffing Unit

Two independent buffers handle different adhesive colors. Cotton wheels clean edges via reciprocation for cleaner, smoother, glossier finish.