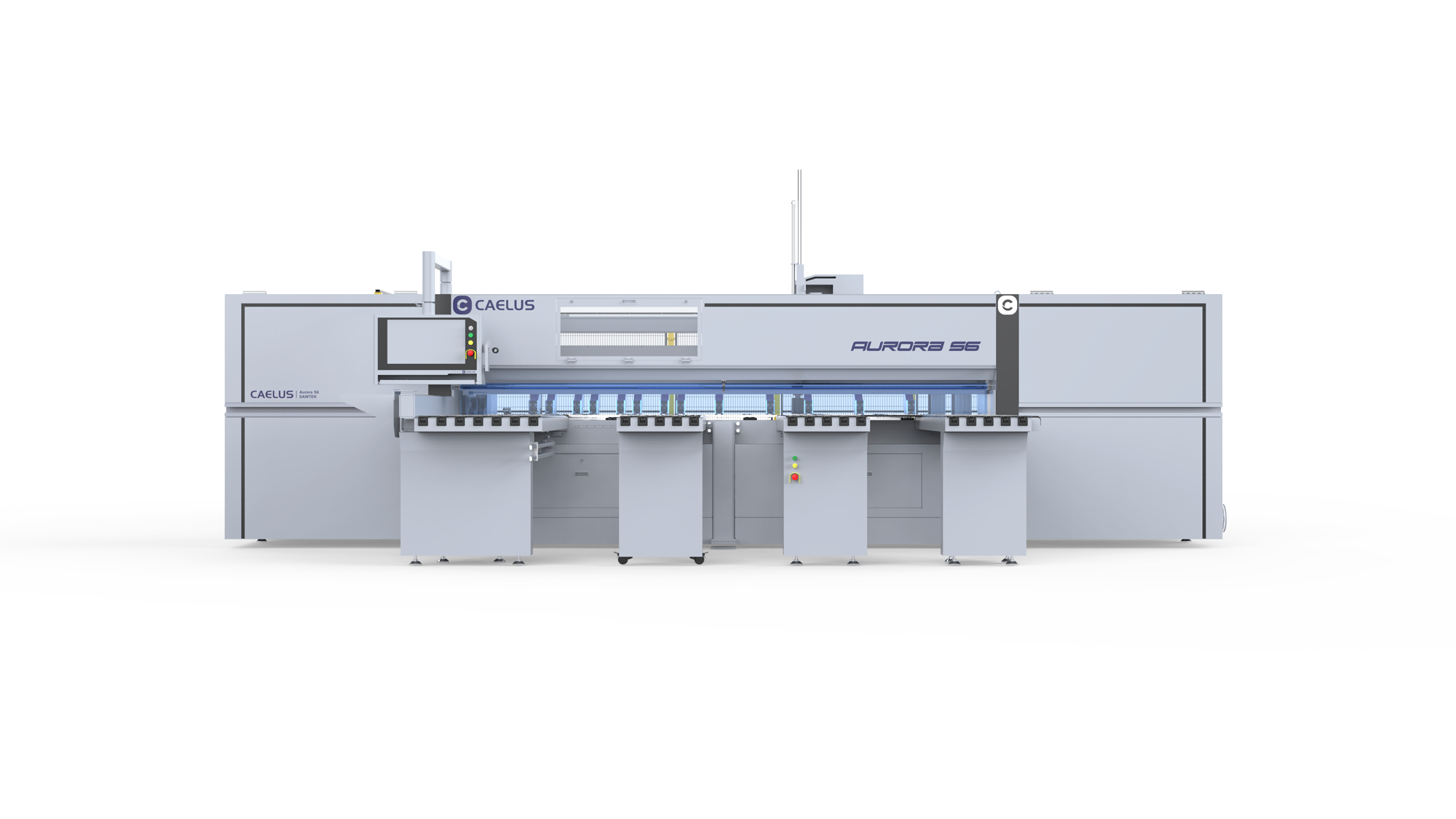

With the three core technologies of "linear motor driven + intelligent labeling + laser detection", the precision and efficiency of workpiece processing are redefined.

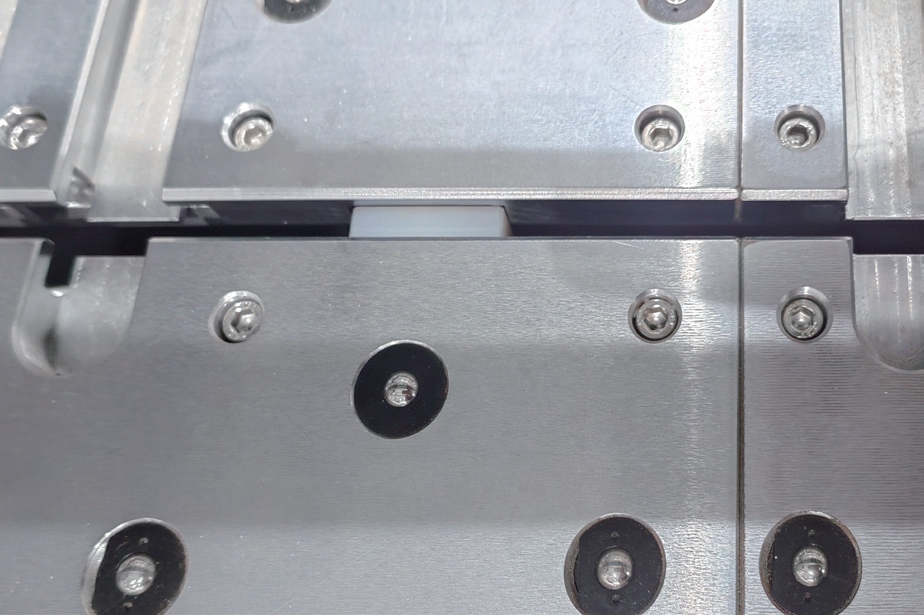

Laser curve detection enables real-time early warning of "banana-shaped" boards.

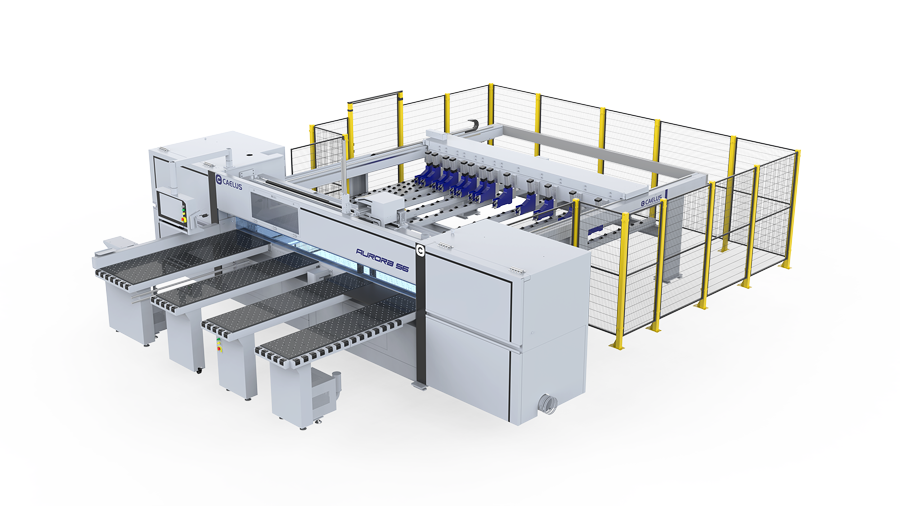

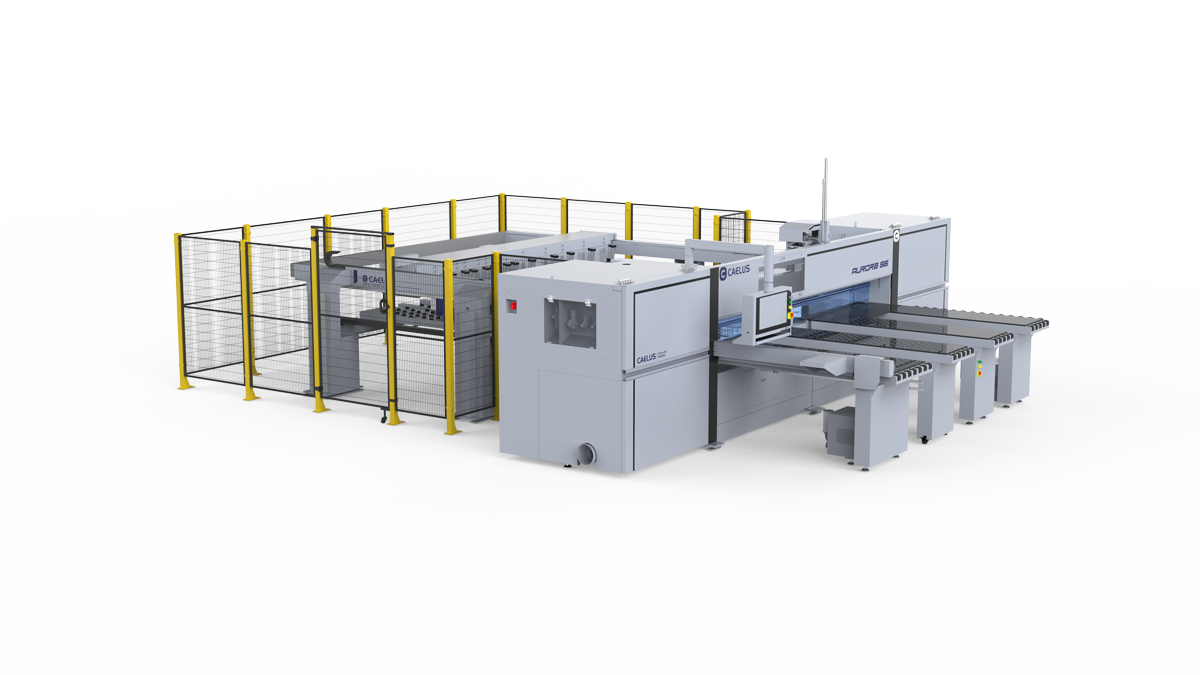

The intelligent labeling system seamlessly integrates with the cutting operation, enabling simultaneous cutting and labeling. lt is equipped with a built-inhigh-pressure air blowing device to remove dust before labeling. with fully automated labeling, it reduces manual intervention and prevents missed orincorrect labeling.

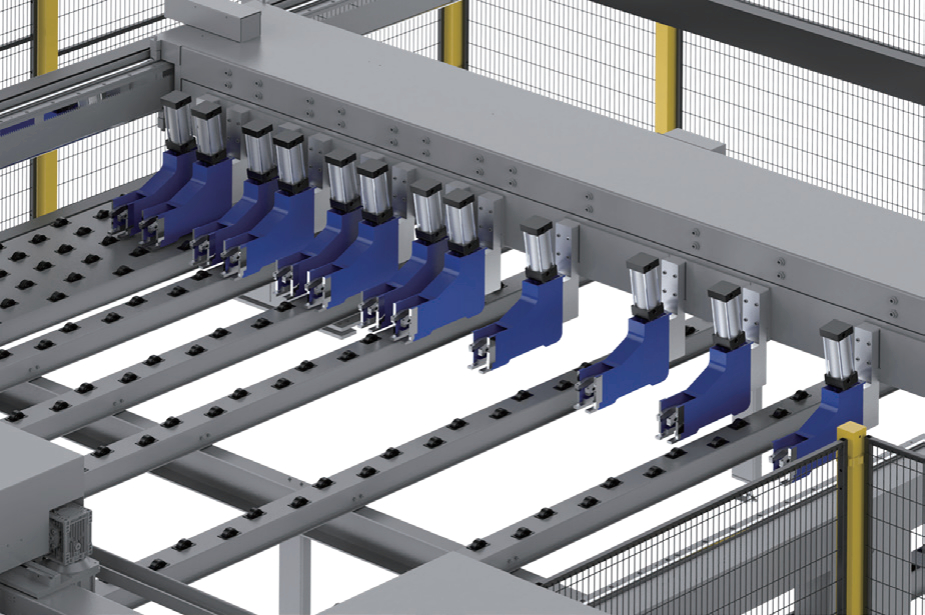

Adaptive control system for pressure beam combinedwith servo-motor driven, achieving rapid upward/downward movement and gentle approaching sequences to maximize operational efficiency while significantly reducing impact forces on both processed materials and worktable.

With higher density clamps and each clam pcontrolled individually, it can firmly grip the workpiece, ensuring optimal sawing results and smartly avoiding special dimensions.