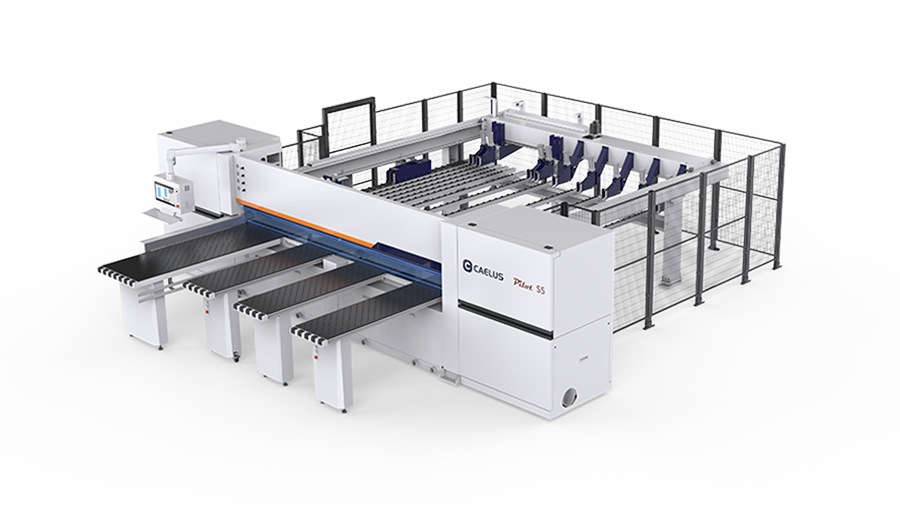

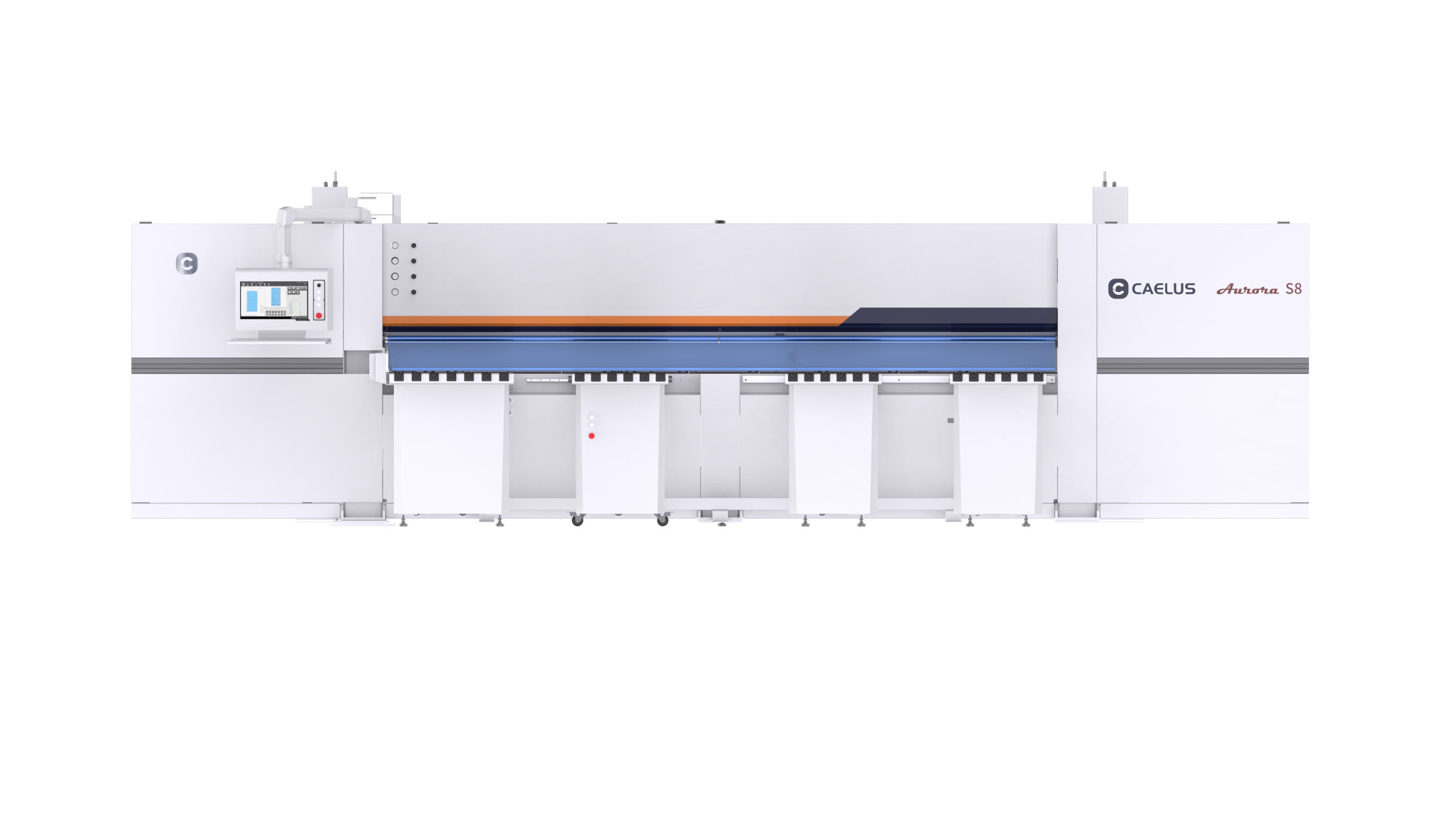

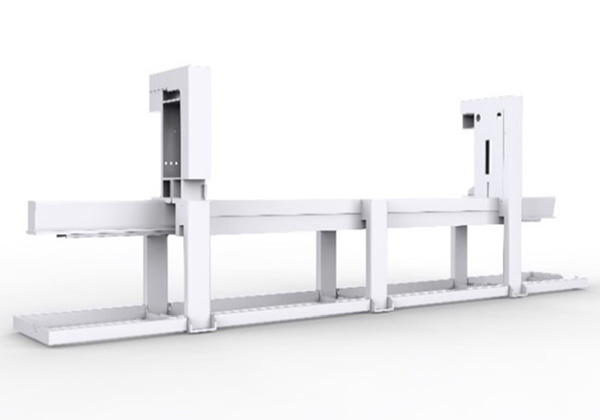

S5 front loading panel saw is used to precisely cut wood panels and other panels with similar cutting characteristics as wood, and connected to a variety of software and equipped with a smart optimization software to improve material utilization.

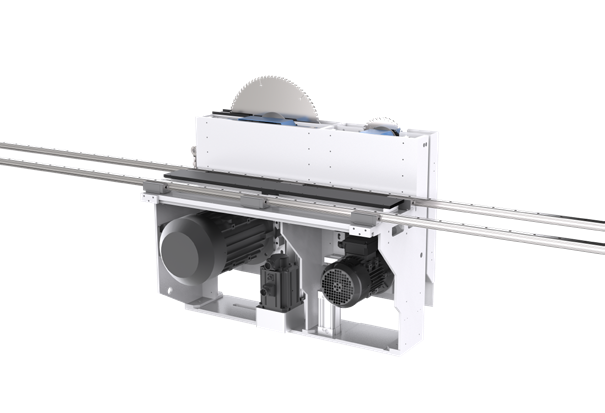

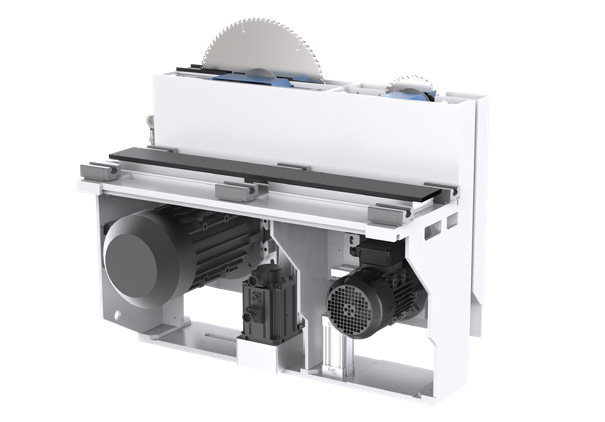

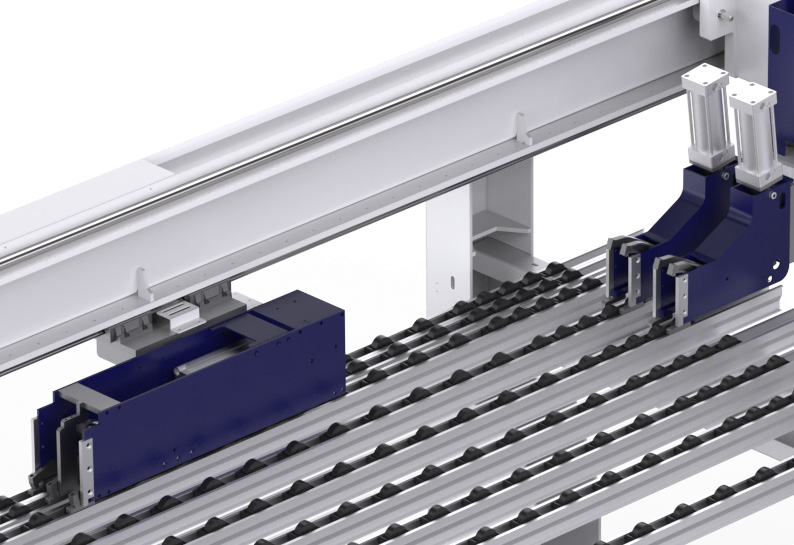

Saw carriage driven by linear servo motor with speed 200m/m

Core Highlights:

- Saw Carriage Drive System: Servo control with high rigidity, precision, and dust-proof linear guide structure, automatically adjusting cutting stroke based on panel width. reducing idle time and increasing efficiency. Maximum cutting speed: 160m/min.

- Main Saw Motor: 22kW (variable frequency) permanent magnet synchronous motor with high torque, low noise, wide speed range, and fast response. Speed automatically decreases when idle, ideal for high-volume cutting. Maximum return speed: 200m/min.

- Independent Lifting Systems: Separate lifting control for main and scoring saws. The main saw uses servo control and electric cylinder for automatic height adjustment based on material thickness, ensuring optimal cutting.

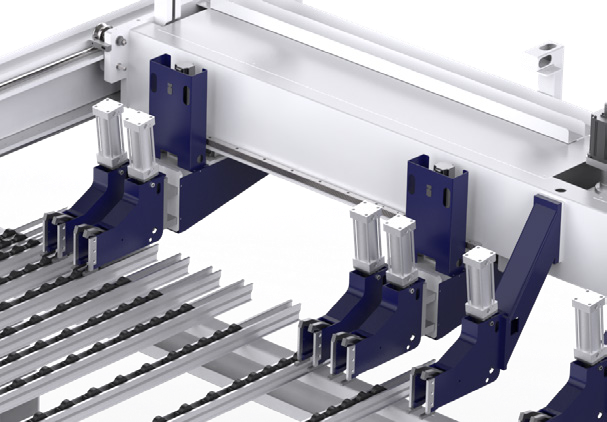

- Servo-Controlled Mechanical Clamps: Two sets of servo-controlled movable clamps adjust to different panel sizes for precise cutting.

- Twin Pusher: Two independent servo-driven pushers allow for simultaneous cutting of two differently sized panels, boosting efficiency by 30%.

- High-Precision Pneumatic Lifting for pressure beam: Dual-rod pneumatic cylinders with special control for automatic positioning, adjusting lifting height based on panel thickness to reduce idle stroke and improve cutting efficiency.

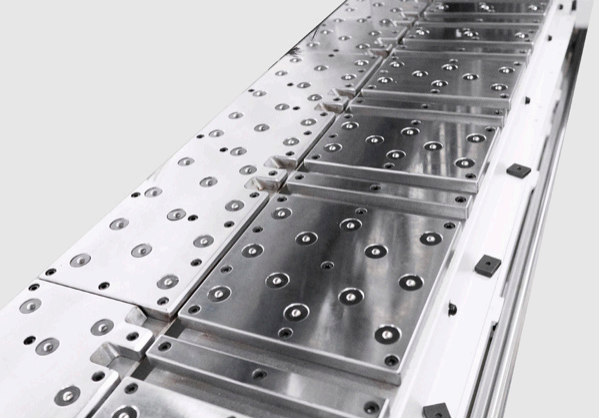

- Air Cushion Steel Table: Ensures smooth movement and protects sensitive surface materials from scratches.