Why is Panel Saw Non-Negotiable for Furniture Factories? In today's rapidly expanding global furniture manufacturing industry, the demand for customized furniture is surging. However, for factory owners, the increase in orders brings not only joy but also enormous challenges to production capacity.

In the panel furniture production chain, cutting is the starting point. If the first cut is off, subsequent edge banding, drilling, and assembly will all fail. Traditional cutting methods are facing a triple blow of "low efficiency, poor precision, and serious material waste." Especially facing the stringent craftsmanship requirements of the European, American, and South Korean markets, ordinary cutting machine can no longer meet the standards.

This is why the Panel Saw has become an indispensable "first lifeline" in modern furniture manufacturing. It is not just a cutting machine, but also a key to building a core competitive advantage for enterprises.

What Is a Panel Saw?

Simply put, a Panel Saw is a core piece of machine specifically designed for precisely cutting large-format engineered wood products (such as particleboard, MDF, and plywood) to the required dimensions.

Unlike traditional table saws, industrial-grade Panel Saws are not simply woodworking tools, but rather a sophisticated cutting system. They boast extremely high stability, automation level, and batch processing capabilities. Their core value lies in "precision": cutting accuracy directly determines whether the edge banding adheres properly, whether the holes align, and whether the assembled product has a satisfactory aesthetic appearance.

As an industry leader, Caelus has redefined this standard. Caelus machine uniformly employs a heavy-duty, high-precision structure, servo/linear drive systems, and an intelligent control architecture, ensuring absolute perpendicularity and flatness in the cut from the source, completely eliminating "edge chipping" and "dimensional deviations."

Types of Panel Saws: From Beginner to Fully Automatic There are many types of Panel Saws on the market; factories should choose the appropriate model based on their production capacity.

Hand-operated precision Panel Saw (Entry Level): An entry-level choice for small factories. While cost-effective, operation relies heavily on manual experience, making it difficult to handle large-scale orders.

Electric sliding Panel Saw (Intermediate): Driven by a motor, it reduces worker fatigue and offers superior precision compared to manual models. Suitable for factories with small to medium production capacity and simple order structures.

Beam Saw cutting machine (Auto Feeding): This is the mainstay for medium-sized factories. Equipped with automatic feeding and clamping systems, it supports multi-sheet stacking, significantly increasing processing speed and makes it ideal for standardized production.

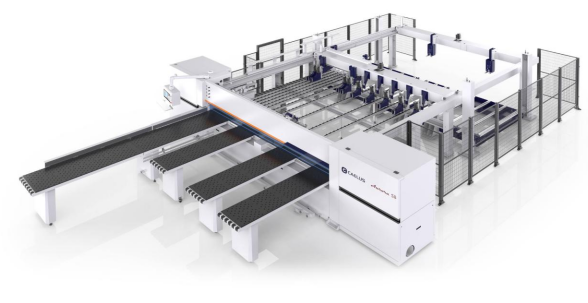

CNC Panel Saw (The Game Changer): This represents the pinnacle of precision, speed, and automation. It not only enables high-speed cutting but also integrates with intelligent warehousing systems. Caelus' CNC Panel Saw combines high speed with flexibility, easily handling both mass production and custom orders (Batch Size 1).

Industrial Panel Saw (High Throughput): Designed for ultra-large-scale factories, supporting continuous high-cycle production. All Caelus models can be seamlessly integrated into smart factories, enabling unmanned operation from loading to unloading.

How Does a Panel Saw Work?

Understanding the working principle of a Panel Saw helps us use it better. Its core process includes: panel clamping → grating scanning of dimensions → sawing → unloading.

Main Saw + Marking Saw Combination: This is the secret weapon to prevent panel chipping. The marking saw first marks a shallow groove on the bottom of the panel, and the main saw then cuts through, ensuring a smooth and flat cut on both sides.

Pressure Beam System: Firmly presses down on the panel during sawing, eliminating any vibration errors.

CNC Positioning System: Caelus machine utilizes precision servo control to keep cutting errors within an astonishing ±0.1mm.

Intelligent Brain: Combined with Cutting Optimization software and the MES system, the machine can automatically calculate the optimal cutting path, achieving Efficient Panel Cutting.

Application Scenarios in Furniture Manufacturing

Panel Saws are active in various furniture manufacturing scenarios:

Cabinet and Wardrobe Factories: Whole-house customization production lines need to handle a large number of panels of different sizes, requiring extremely high precision.

Office Furniture Manufacturing: This is typically large-scale standardized production, where the high throughput advantage of industrial-grade machine is fully demonstrated.

Wooden Door Factories and OEM Manufacturing: machine needs to have extremely strong material adaptability.

Caelus' CNC Panel Saw performs particularly well in these scenarios. With its extremely high order changeover flexibility, it can quickly switch between "batch mode" and "custom mode," handling veneer panels, particleboard, and fire-resistant boards with ease.

Why Top Factories Are Upgrading to CNC Panel Saws?

More and more leading factories are phasing out old machine and upgrading to CNC Panel Saws. The reasons mainly focus on three points:

Precision: Automatic edge banding lines and CNC drilling lines have almost zero tolerance for deviations in previous processes. Caelus's heavy-duty structure ensures consistent accuracy even after prolonged use, preventing cumulative errors.

Productivity: A single high-performance Panel Saw can produce 300-500 panels per day, enough to replace five traditional table saws.

Cost Saving: One person can operate multiple machines, and software-based layout optimization can increase panel utilization by 5-12%, a significant improvement for the low-margin manufacturing industry.

CNC Panel Saw: Pros, Cons & Practical Solutions

Independent Twin Pusher of Panel Saw

Any intelligent machine has its pros and cons; understanding them helps us make informed decisions.

Pros:

High Precision and Stability: Caelus utilizes a servo/linear drive system, resulting in clean cuts with a precision of ±0.1mm.

Automation and Efficiency: Full-process automation significantly reduces reliance on manual work.

Flexible Manufacturing: It is perfectly adaptable to irregularly shaped machining and multi-variety orders.

Intelligent Integration: It seamlessly integrates with MES and intelligent warehousing systems.

Cons (Challenges):

Higher initial investment: A higher barrier to entry compared to manual Panel Saws.

Technical barrier: It requires operators to have software operation skills.

Caelus's Solution:

For initial investment, Caelus offers tiered solutions from entry-level to fully automated models, adaptable to different budgets. Regarding operational difficulty, we have developed a minimalist intelligent control architecture equipped with a fault warning system. Professional technicians provide operation guidance, making the machine both easy to operate and durable.

Ordinary Beam Saw vs. CNC Panel Saw: Detailed Comparison

To help you clarify your understanding, we have created the following comparison table:

Table 1: Beam Saw vs. CNC Panel Saw Comparison

| Feature | Ordinary Beam Saw | CNC Panel Saw |

|---|---|---|

| Automation Level | Medium (Semi-automatic feeding, with some manual handling) | High (Fully automated, supports smart integration) |

| Cutting Precision | High (±0.2mm) | Ultra-High (±0.1mm, reinforced structure) |

| Software System | Basic optimization, limited layout functions | Advanced optimization + MES data connectivity |

| Flexibility | Low (Best for standardized batch orders) | High (Rapid changeover for customized orders) |

| Initial Investment | Moderate | Higher |

| Ideal User | Medium capacity, single order type factories | Large factories, custom furniture, high-end brands |

| Long-term Cost | High labor dependency | Reduced labor & material costs (High utilization) |

Key Technical Parameters Analysis of Panel Saw

When purchasing a precision Panel Saw machine, please pay attention to the following core parameters:

Sawing Speed (m/min): It directly determines production capacity. Caelus's high-speed design perfectly meets the high-speed, high-volume demands of furniture production.

Sawing Accuracy (±0.1mm): It is a core quality indicator, determined by the Machine's structure and servo drive system.

Pressure Beam Structure: Only a heavy-duty pressure beam can ensure absolute stability during cutting.

Software Algorithm: Excellent algorithms can increase the utilization rate of panel processing to over 90%.

Common Cutting Pain Points & Solutions

Common pain points in the industry include significant panel waste, incorrect material selection and marking, non-perpendicular sawing, and unstable operation.

How does the Panel Saw solve these problems?

CNC Precision Positioning: Eliminating dimensional deviations, Caelus's servo system ensures repeatability accuracy.

Automatic Optimized Layout: Greatly reduces waste generation.

QR Code Binding: Full traceability, completely eliminating incorrect material selection. Intelligent anti-misoperation: Infrared protection and fault warning make production safer.

Ultra-durable parts and design: Equipped with GUS cable chains and flexible cables, the cable chains can withstand up to 10 million bends and friction cycles.

How to Choose the Right Panel Saw?

Table 2: Selection Guide by Capacity & Needs

| Production Scale | Order Type | Recommended Machine Solution |

|---|---|---|

| Small (50-100 sheets/day) | Mixed / Custom | Entry-level precision sliding table saw |

| Medium (100-300 sheets/day) | Standardized Batch | Beam saw cutting machine |

| Large (300+ sheets/day) | Mass Customization | CNC Panel Saw (Caelus High-Speed Series) |

| Integration Needs | Smart Factory Line | Industrial Panel Saw with auto-storage |

Choosing a reliable Panel Saw machine manufacturer means you not only buy a Panel Saw machine, but also receive complete support from production planning to after-sales service.

Caelus Panel Saw: Unique Advantages

Caelus stands out in the furniture manufacturing industry. Our core advantages are:

- Stability: Heavy-duty construction reduces vibration and ensures consistent precision for decades.

- Accuracy: Top-of-the-line servo/linear drive system for precise and reliable positioning.

- Speed: Amazing processing speed to meet the most demanding delivery times.

- Flexibility: Extremely high order changeover flexibility, making it a powerful tool for customized production.

Caelus' entire range of machine can be seamlessly integrated into smart factories, providing complete solutions from entry-level precision cutting to fully automated robotic flexible processing.

The Role and Trends of Panel Saw in Furniture Factories

In the smart factories of the future, the Panel Saw will no longer be a standalone machine. It integrates deeply with Manufacturing Execution Systems (MES), working in real-time with automated warehousing, edge banding production lines, and drilling lines to ensure seamless data flow across all stages.

This is precisely the "software-hardware integration" transformation that Caelus is fully committed to—its core lies in optimizing processes through machine interconnection and data-driven approaches, helping furniture manufacturers achieve large-scale personalized customization, thus improving both production flexibility and efficiency.

FAQ

Q1: What is a Panel Saw in furniture manufacturing?

A: It is a specialized machine used to cut large sheets of wood materials (like MDF, plywood) into precise sizes for furniture assembly.

Q2: What's the difference between CNC Panel Saw and regular cutting saw?

A: A CNC Panel Saw uses computer control for higher precision, automation, and optimization, whereas regular saws rely on manual operation.

Q3: Which furniture factories need a Beam Saw Cutting Machine?

A: Factories with medium to high production volumes that require standardized cutting of stacked panels for efficiency.

Q4: How to improve panel cutting efficiency?

A: You can utilize cutting optimization software and upgrade to a machine with fast servo drives and auto-loading capabilities.

Q5: Why is my Panel Saw's cutting precision inaccurate?

A: It could be due to machine vibration, worn blades, or lack of a heavy-duty pressure beam. Caelus machines solve this with robust structural Design.

Conclusion: Panel Saw = Core Competitiveness for furniture manufacturing

The panel cutting process directly determines a factory's product quality, production efficiency, and cost baseline. Automation, intelligence, and flexibility are the inevitable development for panel cutting machine, determining the development and future of major furniture factories.

Choosing Caelus means choosing to embrace the future of efficient panel cutting. With our heavy-duty, high-precision structure, servo drive system, and intelligent integration capabilities, we help you maintain a competitive edge in the fierce market competition